Battery selection for a given wireless Internet of Things (IoT) node or wearables design is complex. Among the important factors are: how long the device is expected to operate with a single battery; the choice between various primary and secondary battery chemistries; the nominal and cut-off voltage of the electronics; the energy/current consumption profile, the maximum pulse current, and frequency; and environmental considerations such as operating temperature and shock and vibration conditions.

This FAQ focuses on the available options for batteries and charging technologies for wireless IoT nodes and wearables. The use of supercapacitors and/or energy harvesting is not included in this discussion. In some designs, supercapacitors are used to meet pulse power needs while enabling the use of smaller batteries. EEWorld recently published a three-part series on supercapacitors. The first article in the series is: “Supercapacitor operation – a higher power source.”

And some systems employ energy harvesting to either replace or supplement batteries. For a discussion of using energy harvesting with IoT devices, please see EEWorld’s recently-published three-part series of articles. The first article in the series is: “Energy harvesting applications, architectures, and the massive IoT.”

Battery chemistry alternatives

In addition to small format alkaline cells (such as AA and AAA alkaline batteries), battery chemistries commonly used to power wireless IoT nodes and wearables include:

- Primary lithium cylindrical cells

- Lithium-Thionyl chloride (Li-SOCl2) chemistry, which exhibits the highest nominal voltage among primary battery chemistries (3.6 V). These batteries have also the highest energy density and can store it for up to 20 years. They are very sturdy and can withstand very high temperatures and strong vibrations.

- Lithium-manganese dioxide (Li-MnO2) chemistry – 3V. These cells have a lower nominal voltage of 3.0 V vs. 3.6 V. If the application’s electronic design allows a cut-off voltage below 2.5 V, these cells can be one of the most economic options with a good trade-off between energy and power.

- The primary lithium button and coin cells have a battery voltage of 3V, almost double that of normal alkaline or manganese batteries. The voltage characteristics remain stable even for a long period of discharge. The annual self-discharge rate at room temperature and normal humidity is less than 1% of the nominal capacity.

- Button type (BR) lithium cells are made from lithium alloy and carbon mono-fluoride gel. This cell type has a voltage of 3V, and it drops to 2.2V when discharged. It has a low self-discharge rate and is ideal for devices that are meant to run for a longer duration and have low power requirements. Button cells are usually used in RTC and memory backups. Common models include BR2032 (190mAh), BR1225 (48mAh).

- Coin type (CR) lithium cells have a higher discharge rate compared to button type. They are used in devices that are not meant to be run for super long durations but require higher pulse currents. The CR type cells use manganese dioxide as the cathode, which reduces the battery’s internal impedance. They are used where pulse current is required in applications like remotes, small wireless devices such as wireless IoT nodes, some wearables, and flashes. Common models include CR2032 (225mAh), CR2025 (165mAh)

- Rechargeable lithium

- Li-ion/polymer cells are rated at 3.7V, rechargeable Li-ion coin cell voltages may be up to three times higher than traditional Cd-Ni or MH-Ni types. This means more power in less space. There is no memory effect, and they are reliable, maintaining 80% capacity after 500 cycles.

- Lithium-titanate battery (LTO) is a type of rechargeable battery that has the advantage of being faster to charge than other lithium-ion batteries, but the disadvantage of having a much lower energy density. A disadvantage of lithium-titanate batteries is that they have a lower inherent voltage (2.4V), which leads to lower specific energy than conventional lithium-ion battery technologies, which have an inherent voltage of 3.7V.

- Rechargeable lithium-ion polymer (LiPo) coin cells are rated for 4.35V with capacities from 18- to 80-mAh. The higher voltage translates to more overall energy compared with conventional Li-ions. Most LiPo batteries are not rated to last longer than 300 charge cycles.

Dealing with high power pulses

ANT+, Bluetooth v4.0, ZigBee, and Wi-Fi are all wireless standards with either a specific focus on or recent additions addressing simpler but low power, or ultra low power wireless technologies. The different technologies can roughly be split into the following categories:

- Low power (average current consumption in a node 5-50+ mA):

- Wi-Fi direct

- ZigBee

- Bluetooth versions prior to v4.0.

- Ultra low power (average current consumption <1 mA)

- ANT+

- Bluetooth v4.0 (which includes Bluetooth low energy as a hallmark feature).

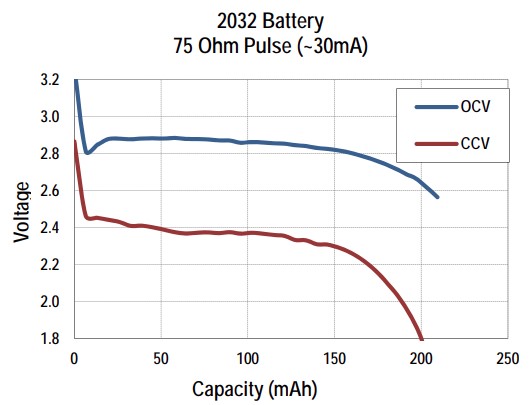

Impact of high pulse power use (CCV) on a CR2032 coin cell in a typical wireless IoT node design. (Image: Energizer)

Unlike traditional coin cell applications, which continuously draw a stable current, a wireless application subjects the battery to a very different usage pattern. When the radio circuitry is activated, it can draw anywhere from 10-80 mA, depending on technology, vendor, and implementation. This drain far exceeds the rated drain current condition (about 200μA for a CR2032) for which the battery capacity is stated in the battery datasheet.

Batteries in low pulse drain applications will typically have a capacity near to the device average drain. However, for high pulse applications such as wireless IoT nodes, the voltage drop of the battery during the pulse (CCV) needs to be accounted for.

For example, the CCV pulse in the image below for a CR2032 coin cell would meet a 2V cutoff much sooner than the average drain CCV due to the voltage drop during the pulse.

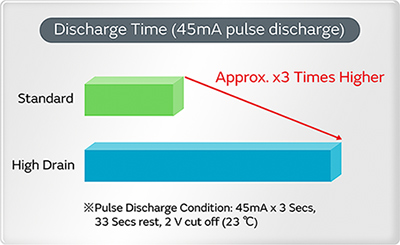

The High Drain lithium coin batteries from Murata are designed for tracking devices for logistics and asset management by adopting Low Power Wide Area (LPWA) networks such as LoRa and SIGFOX as well as for outdoor infrastructures, FA control systems, and environment monitoring sensors. The maximum pulse discharge current is about double compared to Murata’s Standard type coin cells. And compared to the Standard, the High Drain maintains a high current even when the discharge continues. The maximum pulse discharge current has been doubled to 50mA compared to that of Standard. This model can now be used for LPWA communication devices, such as LoRa with high peak currents, etc. which is difficult to handle with standard coin lithium batteries.

And the High Drain lithium coin cells from Murata have a capacity usage rate about 3 times higher compared to Murata’s Standard type coin cells. Compared with the Standard, since the High Drain can maintain a high voltage even when the discharge continues, the capacity of the battery can be used more effectively.

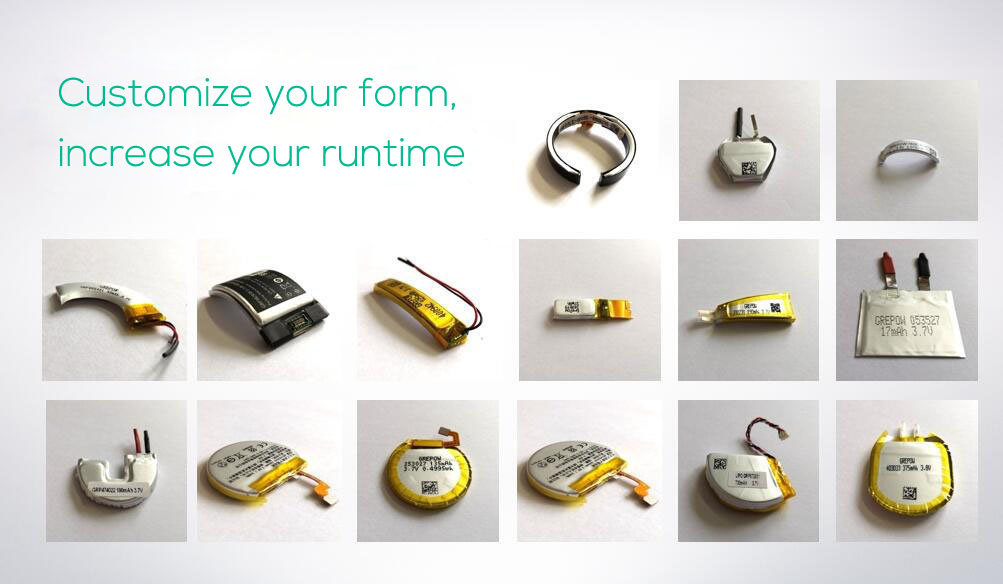

Grepow Battery offers lithium-polymer rechargeable batteries for wireless IoT nodes and wearables in a wide variety of shapes beyond conventional cylindrical and coin formats. Standard shapes

include ultra-thin batteries, curved batteries, round batteries, triangle batteries, rectangular batteries, hexagon batteries, ultra-narrow batteries, “C” shaped batteries, “D” shaped batteries, and polygon batteries. These batteries are compact: 0.4mm to 8mm in thickness and 6mm to 50mm in width. They support high rate discharge, fast charging capacity and are offered in two operating temperature ranges: -50°C to +50°C or -20°C to +80°C.

Battery charging

The BQ25125 from Texas Instruments is an example of a highly integrated battery charge management IC for Li-ion/Li-polymer batteries that integrates the most common functions for wearable devices: Linear charger, regulated output, load switch, manual reset with timer, and battery voltage monitor. The integrated buck converter is a high efficiency, low IQ switcher using DCS-Control (DCS is Direct Control with Seamless transition into power-save mode) that extends light load efficiency down to 10-µA load currents. The BQ25125 is designed for use in a range of applications, including:

- Smartwatches and other wearable devices

- Fitness accessories

- Health monitoring medical accessories

- Rechargeable toys

- True wireless headsets (TWS)

- Wirelessly charged products

For users of Lithium-titanate batteries, Torex Semiconductor Ltd. has recently developed the XC6240 charging regulator ICs and XC6140 battery voltage monitoring ICs, specialized for batteries compatible with CV (constant-voltage) charging. Both of these products are available with compact, low-profile packages (XC6240: USPN-4, USP-6B06 / XC6140: USPQ-4B05) as well as SSOT-24, allowing them to be mounted in devices requiring smaller sizes or lower profiles in a variety of applications.

Secured inductive charging

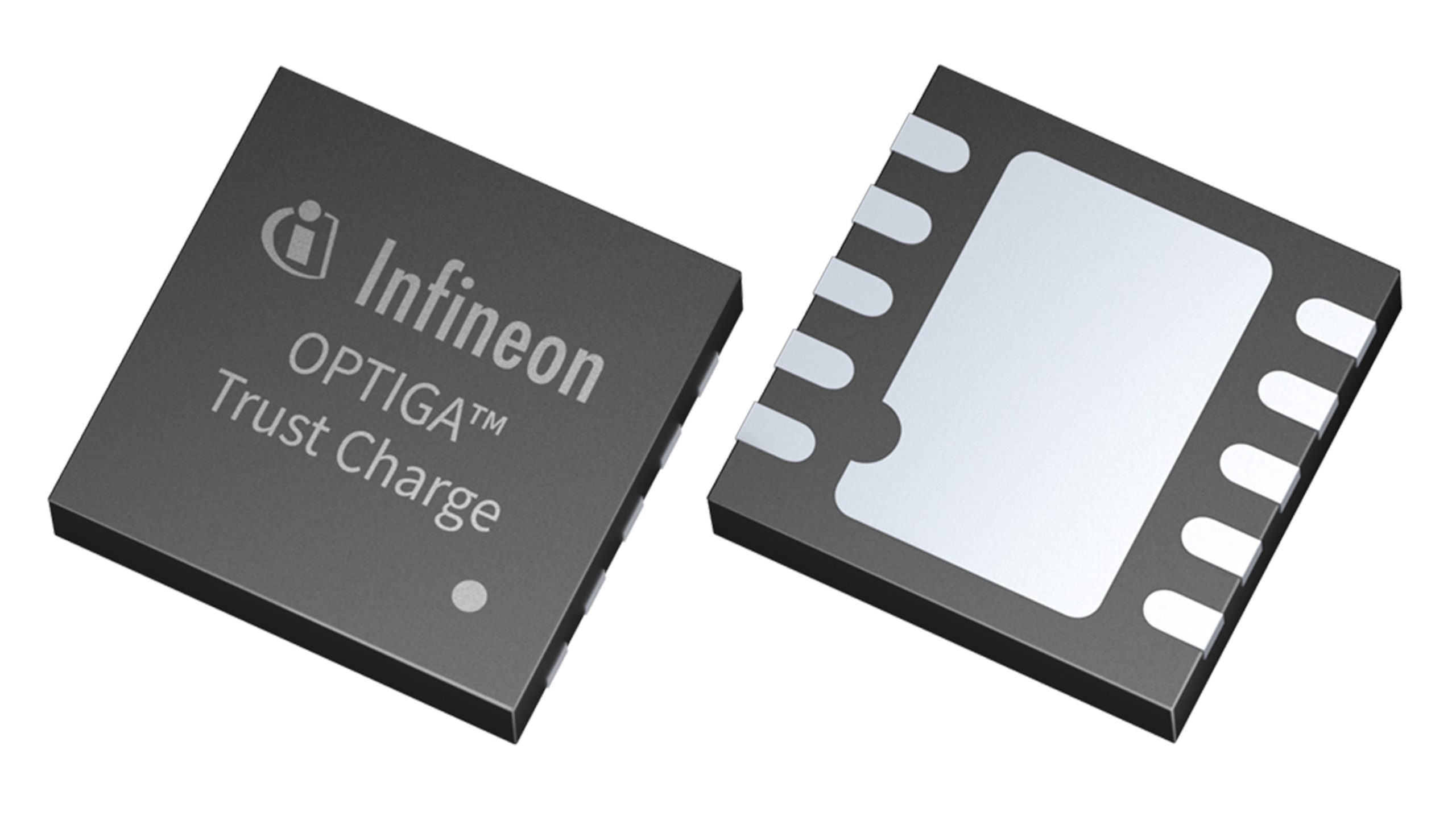

Infineon Technologies has extended its OPTIGA™ Trust product family with a dedicated solution for secured inductive charging. The new OPTIGA Trust Charge is the industry’s first embedded security solution that is usable for the Qi 1.3 wireless charging standard. It addresses chargers for small personal electronic devices like smartphones, earbuds, tablets, wearables, or health tech devices with a charging power of up to 15W

While wireless charging is convenient and hence an increase in demand, an inaccurate power supply can be harmful to the handheld’s battery lifetime and, in the worst case, the user as well. Device authentication with OPTIGA Trust Charge helps to prevent damaging consumer devices with dangerous, fake chargers and protects consumer brands from reputation issues.

The Wireless Power Consortium (WPC) issues the Qi standard and tests and certifies devices accordingly. The new 1.3 version of this standard requires strong cryptographic authentication for wireless charging devices. The wireless charger can authenticate itself to the charging device and prove that it is Qi 1.3 certified. Only then will the device be charged with maximum power. Infineon recommends at least EAL4+ certification on the hardware that stores keys and certificates.

The first three FAQs in this series on powering wireless IoT nodes and wearables considered the various power components available to designers, the instruments and tools that can be used to validate power system performance, and the available choices for batteries and charging. The final FAQ will delve into the instruments and tools available for battery emulation and battery life analysis and maximization for wireless IoT sensor nodes and wearables.

References

High pulse drain impact on CR2032 coin cell battery capacity, Nordic Semiconductor

Lithium Coin Handbook and Application Manual, Energizer

Powering Wireless and Bluetooth LE products with batteries, Argenox

Which types of batteries for your IoT devices?, Saft