by Luca Vezzadini, ZIVAN The urgency of mitigating climate change and reducing greenhouse gas emissions has prompted businesses to adopt more sustainable transportation solutions, particularly electric vehicles (EVs). Lithium-ion batteries (LIBs) are at the forefront of electrification. McKinsey predicted that the entire LIB chain, from mining through recycling, could grow by over 30% annually from 2022…

April 2024 Issue: Internet of Things Handbook

Engineering connections REMEMBER when the estimated number of connected devices in 2005 was around six billion, followed about five years later with the acronym “IoT” achieving buzzword/hype status? Now fast forward to next year, when that number is expected to skyrocket to a staggering 75 billion, or roughly nine devices per person on the planet.…

Liquid cooled battery charger available in compact form

Bel Fuse Inc. is announcing the release of its BCN25-1000 Series — a 25 kW, liquid-cooled battery charger that converts 3-phase AC voltage to DC voltage.

Online calculator assists in energy-harvesting designs

Nexperia announced the release of the Energy Balance Calculator. A powerful web-based tool designed to assist battery management engineers in maximizing the battery life of their applications. The calculator facilitates the integration of Nexperia’s Energy Harvesting PMICs into their systems by providing engineers with precise data for informed decision-making. At the core of Nexperia’s Energy Harvesting PMICs…

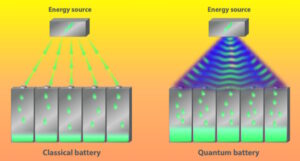

How can quantum sensors and quantum batteries improve electric vehicle operation?

In the near term, quantum sensors are being developed that can more accurately measure EV battery capacity, assess battery safety, and reduce vehicle weight. In the longer term, quantum batteries have been proposed that could dramatically improve the speed and efficiency of battery charging. The energy remaining in an EV battery has been estimated using…

February 2024 Issue: Power Electronics Handbook

Cold starts, hot power markets, and great expectations Recent cold spells across the United States have shifted the focus from “range anxiety” in electric vehicles (EVs) to concerns about their performance in cold…how they start, and how far they can go. Buzzworthy? Apparently. Newsworthy? Maybe, but it’s not new news. Reflecting on a youthful…

Research shows improvements for fast-charging of Li-ion batteries

Researchers at Chung-Ang University used high-concentration electrolytes to improve safety and prevent cell swelling caused by lithium plating. To achieve a greater adaption of electric vehicles, the automotive industry needs fast-charging batteries that don’t compromise energy density. Lithium plating for ultra-fast charging raises safety concerns due to high cell polarization, requiring careful attention. During fast…

Battery connector line include models for high signal and current

KYOCERA AVX expanded its robust and extremely user-friendly 9155-800 Series vertical-mate, 2.0mm-pitch battery connectors with the addition of new seven- and eight-position models to satisfy customer demand for higher signal and current capabilities. These new additions also further expand its 9155 family of battery connectors, which already offered the broadest selection of standard battery connectors…

24mm lithium coin cell holder space-saving and top-loading

A breakthrough lithium coin cell holder for maximizing PC board capacity when installing high-capacity 2477 lithium coin cells in high-density applications is now available from Keystone Electronics. Its top-loading design allows for minimal footprint board layouts without restricting battery access in devices. This sturdy holder is supplied in a thru-hole version and is extremely rugged,…

$131 Million to boost America’s battery supply chain and supercharge electric vehicle innovation

The US Department of Energy (DOE) today announced more than $131 million for projects to advance research and development (R&D) in electric vehicle (EV) batteries and charging systems and funding for a consortium to address critical priorities for the next phase of widescale EV commercialization. The advanced battery consortium will work towards developing advanced technologies…