Consumer (sometimes referred to as commercial) lithium (Li) batteries offer better performance compared with lower-cost alkaline, nickel-cadmium (NiCd), or nickel metal hydride (NiMH) alternatives, but industrial Li batteries are even higher in performance. This FAQ looks at examples of chemistries for primary and secondary Li batteries in consumer and industrial devices including the use of…

What’s different about industrial and medical Li batteries?

In many cases, the difference is related to regulatory demands versus environmental demands. Both segments require high levels of safety and performance from Li batteries. Medical applications have numerous strict regulatory and certification requirements while industrial systems tend to have more challenging environmental performance needs. This FAQ looks at the extensive standards defined for medical…

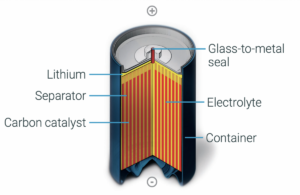

How do the six most common Li primary chemistries compare?

Rechargeable lithium-ion batteries get a lot of headlines, but primary Li battery chemistries are the workhorses in a large number of industrial, medical, consumer, and other applications. This article looks at the performance tradeoffs and typical applications for the six most common Li primary chemistries including LiCFX (lithium poly carbon monofluoride) LiMN02 (lithium manganese dioxide),…

How can primary Li batteries contribute to sustainability?

A lot has been written regarding rechargeable lithium (LI) batteries and sustainability. Primary (non-rechargeable) Li batteries can also make major contributions to improving the sustainability of the systems where they are used. This FAQ reviews some of the factors related to the sustainability of primary Li batteries including key performance indicators (KPIs), downcycling versus recycling,…

Automated disassembly line aims to make battery recycling safer, faster

From Oak Ridge National Laboratory Researchers at Oak Ridge National Laboratory developed a robotic disassembly system for used electric vehicle batteries to make the process safer, more efficient and less costly. Credit: Jenny Woodbery/ORNL, U.S. Dept. of Energy Researchers at the Department of Energy’s Oak Ridge National Laboratory have developed a robotic disassembly system for…

Lithium battery recycler to go public

Li-Cycle Holdings Corp. (“Li-Cycle” or “the Company”) today announced that it has completed its previously announced business combination with Peridot Acquisition Corp. (“Peridot”). The ticker symbols for the common stock and warrants of Peridot will change from “PDAC” and “PDAC.WS” to “LICY” and “LICY.WS”, respectively, and will begin trading on the New York Stock Exchange…