by Luca Vezzadini, ZIVAN The urgency of mitigating climate change and reducing greenhouse gas emissions has prompted businesses to adopt more sustainable transportation solutions, particularly electric vehicles (EVs). Lithium-ion batteries (LIBs) are at the forefront of electrification. McKinsey predicted that the entire LIB chain, from mining through recycling, could grow by over 30% annually from 2022…

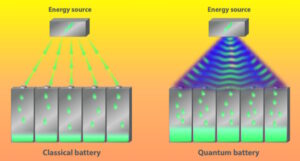

How can quantum sensors and quantum batteries improve electric vehicle operation?

In the near term, quantum sensors are being developed that can more accurately measure EV battery capacity, assess battery safety, and reduce vehicle weight. In the longer term, quantum batteries have been proposed that could dramatically improve the speed and efficiency of battery charging. The energy remaining in an EV battery has been estimated using…

Research shows improvements for fast-charging of Li-ion batteries

Researchers at Chung-Ang University used high-concentration electrolytes to improve safety and prevent cell swelling caused by lithium plating. To achieve a greater adaption of electric vehicles, the automotive industry needs fast-charging batteries that don’t compromise energy density. Lithium plating for ultra-fast charging raises safety concerns due to high cell polarization, requiring careful attention. During fast…

What are e-bikes?

In this article, we’ll explore the types of e-bikes available and their features. In terms of e-mobility, e-bikes stand out as a compact, affordable option for many.

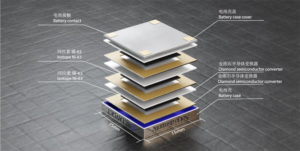

Betavolt achieves miniaturization of atomic batteries with 50-year autonomy

Editor’s note: Read more and watch colleague James Anderton on engineering.com TV describe what this “nuclear battery” means to you and me and the charging cords we carry — or not. Check it out here. Beijing’s Betavolt New Energy Technology Co., Ltd. announced a miniature atomic energy battery that combines nickel 63 nuclear isotope decay…

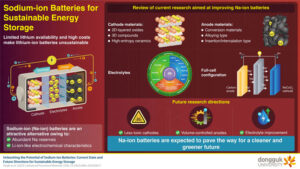

Sodium-ion batteries: the future of sustainable energy storage

Lithium-ion batteries (LIBs) have become essential for energy storage systems. The limited availability of lithium, however, has raised concerns about the sustainability of LIBs. In a new study, scientists from Dongguk University reviewed the recent advances in sodium-ion battery technology, a potential alternative to LIBs. Their findings can inspire young researchers to combat the current…

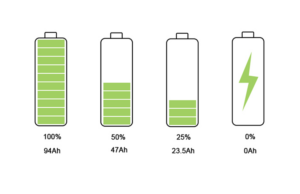

What is an EV battery state of charge (SOC)?

An electric vehicle (EV) battery state of charge (SOC) represents energy levels as a percentage. Analogous to an internal combustion engine (ICE) fuel gauge, SOC clearly indicates available energy that directly corresponds to the driving range. This article explains how SOC is calculated and explores the different methods used to determine these calculations. It also…

What is a lithium battery digital passport?

A digital battery passport provides easy access to structured, reliable, and complete information about the battery. This fresh initiative in the US lithium battery landscape aims to simplify consumers’ choice and use of batteries. The US government agencies are working on battery passport requirements, centralizing battery specifications and pertinent details, making it user-friendly for the…

October 2023 Issue: Power & Energy Efficiency Handbook

Engineering a green mindset and sustainable future Growing up in the pre-2000s era with a power electronics engineer for a father, my family’s first introduction to power and energy efficiency efforts was primarily analog. The word “vampire” was associated with a TV show called Dark Shadows; it had nothing to do with standby power…

Battery testing: critical to the rise of electric vehicles

When designing a battery into an EV, you must perform rigorous testing to understand a battery’s performance. Electric vehicles (EVs) accounted for 13% of global vehicle sales in 2022 and are forecasted to reach 30% of global vehicle sales by 2030. The industry needs to continue working on making EVs affordable to support this transition…