Keeping EV batteries cooled is the most common thermal management concern. However, batteries used in cold climates often benefit from being heated when temperatures fall. When undergoing fast charging or extra fast charging (XFC) batteries may need additional levels of cooling. This FAQ first considers various active and passive cooling technologies for EV batteries. It then looks at the special challenges facing EV drivers in cold climates such as Alaska. It closes with a brief look at battery thermal management system (BTMS) design challenges to overcome before XFC can become a reality.

A BTMS is necessary to prevent battery degradation or damage from various thermal thresholds:

- Below 0 °C (32 °F), electrochemical reactions slow with a corresponding decrease in power, acceleration, and driving range. Higher potential for battery damage during charging (low-temperature operation is discussed in more detail below in the section ‘Thermoelectric BTMS and Alaska.’

- Above 30 °C (86 °F), battery performance also degrades, reducing effective power density and acceleration capability. This can be particularly problematic since, at these temperatures, additional power is often needed for the vehicle air conditioner.

- Starting at about 40 °C (104 °F), irreversible damage to the battery can occur.

- Between 70 and 100 °C, thermal runaway can begin causing a chain reaction that destroys the cell and spreads to adjacent cells, eventually destroying the entire pack.

The choice between active and passive cooling of EV batteries is based on various performance and economic tradeoffs. Active cooling almost always results in higher battery performance, but it also costs more, and not every EV buyer wants to pay for high performance. For example, while Tesla uses active liquid cooling to achieve maximum performance, the Chevrolet Bolt uses liquid cooling to help minimize the size of the battery pack. The Leaf from Nissan cools its batteries using conditioned air from the cabin, a minimalist form of active cooling that results in a low-cost solution. Other EV makers use a variety of passive and active cooling technologies.

Passive cooling delivers the lowest cooling performance, makes the smallest BTMS, is the lightest weight, has minimum points of failure, and uses no battery power. But it is the least efficient approach. Active cooling is more efficient but uses some amount of battery power. For example, forced air cooling offers improved efficiency but requires a fan motor that can fail. Various forms of liquid cooling are the most efficient and most costly BTMS technologies. And liquid cooling requires a pump that consumes even more power than most forced-air cooling systems.

Liquid cooling BTMS

Liquid cooling is compact and delivers high cooling performance (Figure 1). It is the most common BTMS technology. The liquid used ranges from water to various refrigerants or oils. The liquid can flow directly across the battery cells but often flows through channels in a cold plate to provide indirect cooling to the battery pack.

Figure 1: Liquid-cooled battery from a Chevy Bolt. (Image: Advanced Thermal Solutions)

Direct-contact or dielectric liquid cooling uses a medium such as mineral oil in which to immerse the cells. Indirect contact liquid cooling often uses a mixture of ethylene glycol and water and can take various physical embodiments, including Flowing through a jacket around the battery module; Discrete tubing inside each module, or; Putting the battery modules on a cooling/heating plate. Direct-contact cooling is not usually found in consumer EVs. Indirect contact designs are preferred since they are safer and provide better isolation between the battery module and the environment. A heat exchanger can be added to the system to help heat the cabin during cold weather.

Air cooling BTMS

Like liquid cooling, air cooling can be passive or active. In a passive system, the intake air comes directly from the atmosphere around the vehicle or the cabin. Passive air cooling systems are limited to several hundred watts of dissipation. In an active system, the intake air can be conditioned air from a heater of an evaporator of an air conditioner. Active air cooling is usually limited to 1kW of cooling and can include additional cooling or heating for the cabin (Figure 2).

Figure 2: Air-cooled Nissan Leaf battery pack. (Image: Advanced Thermal Solutions)

Refrigerants, PCMs, and heat pipes

Refrigerants, phase change materials (PCMs), and heat pipes are occasionally used in EV BTMS designs. A direct refrigerant system is a variation on liquid cooling that uses refrigerant as the heat transfer fluid circulating in the battery pack. It is an adaption of air conditioning technology. PCMs can be used as a thermal conductor and buffer in liquid cooling or air cooling BTMS to help manage the battery core temperature. PCMs release/absorb sufficient energy at the liquid/solid phase transition to provide useful levels of heat transfer.

While refrigerants and PCMs are variations on active cooling, heat pipes are a passive cooling technology. A heat pipe is a sealed tube containing a liquid such as a refrigerant or water. It’s a closed system where the liquid is vaporized by a heat source (such as a battery pack) and removed to the surrounding environment by condensing the liquid on the cold side using cooling fins to dissipate the heat.

Thermoelectric BTMS and Alaska

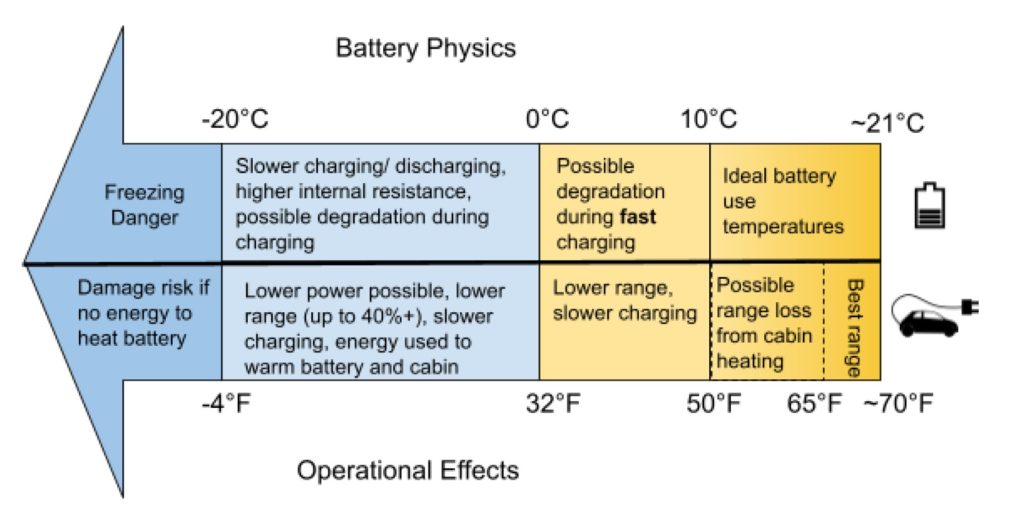

Thermoelectric modules can be used as part of an active or passive EV BTMS. In an active design, the thermoelectric modules can be combined with a cold plate with a cooling liquid pumped through it, or a fan and heat sinks can be used for a forced convection design. Passive thermoelectric cooling BTMS tend to be limited in cooling capability. In any case, the use of thermoelectric technology can add significantly to BTMS costs. However, in cold climates, the use of thermoelectric technology can produce a system that can cool or heat the battery pack as needed simply by reversing the polarity of the electrodes on the thermoelectric module. There are three low-temperature thresholds that EV designers need to consider when designing for cold climates (Figure 3):

- Under 10°C (50°F): Fast charging becomes potentially harmful; lithium plating and permanent degradation can occur when fast charging is below this threshold.

- Under 0°C (32°F): Charging is limited to Level 1. Faster charging can result in lithium plating, and permanent degradation can occur. This is the lowest temperature specified for the normal use of standard Li-ion batteries.

- Under -20°C (-4°F): This is the danger zone. It is typically the lowest specified storage temperature for Li-ions. The battery may not survive prolonged temperatures below this threshold. At -20°C, the battery will require significantly slower charging, and its discharging power capabilities will be reduced.

Figure 3: Low-temperature effects on EV batteries. (Image: Alaska Center for Energy and Power)

Cooling batteries under XFC

XFC technology can deliver 400kW or more at 800Vdc, enabling drivers to charge an EV battery 80% in 8 to 10 minutes. XFC can only be used with specially-designed battery chemistries, battery packs, and BTMS. If not managed properly, XFC can result in battery temperatures over 500 °F that can damage the batteries and other system components. To withstand the thermal demands of XFC, the charging station electronics, cable, and EV battery all require sound and high-performance thermal design. Some proposed systems include a liquid cooling loop integrated with the charging cable and connector. An additional liquid connection between the charging cable and the vehicle can enable liquid flow to cool the battery and the cable and connector during XFC (Figure 4).

Figure 4: EV charger with built-in liquid cooling connections. (Image: Aved)

A robust and oversized BTMS will be required to support XFC. The size of the BTMS is expected to increase from 1–5 kW to 15–25 kW. Other BTMS design challenges to be overcome before XFC can become a reality include:

- The cell-to-cell imbalance due to XFC can reduce the longevity and cycle life cost of the cells. Improved active BTMS technologies will be required to manage those cell-to-cell imbalances and prevent negative effects from XFC.

- Cell design will need to be reconsidered with an increased emphasis on managing temperature variations inside individual cells and temperature imbalances across a battery pack when XFC is used.

- The average lifetime temperature of a cell directly affects the cell’s cycle life. Frequent XFC use will increase the average lifetime cell temperature, negatively impacting cell cycle lives.

Summary

An effective BTMS is required to maintain EV batteries within upper and lower temperature boundaries. If the batteries get too hot or too cold, their performance can be diminished, and they can experience permanent damage. Designers can choose between a variety of passive and active cooling technologies to manage the thermal environment of EV batteries. In the longer term, higher-performance BTMS will be required to enable the use of XFC technology.

References

A Detailed Review on Electric Vehicles Battery Thermal Management System, Materials Science, and Engineering

Cold Weather Issues for Electric Vehicles (EVs) in Alaska, Alaska Center for Energy and Power

Enabling Fast Charging – Battery Thermal Considerations, U.S. Department of Energy Office of Scientific and Technical Information

Industry Developments in Thermal Management of Electric Vehicle Batteries, Advanced Thermal Solutions

The costs and benefits of active cooling, Aved

What EVs have battery thermal management systems

Basically all of them to some degree.

This is very informative, thank you!

I am doing a capstone project for eletrical engineering, and we are trying to simulate an Battery Eletric boat. I am working on the BTMS.

What would be a rough ball park of how much power is consumed by an Active liquid cooled BTM system in 70 degrees F for constant acceleration? I am sure it depends on a lot of variables, I am just tyring to get a starting point. Would a majority of the consumed power be from the pumps?

V/r

Chase

It was very informative. Thanks

I am working on the design project of electric car air conditioning system in hot, dry and cold weather. Can anyone guide?

nima284@yahoo.com