The traditional model railroad power and control has transitioned from simple hardwired loops to advanced networking in the past decades, bringing many benefits and a few drawbacks.

Batteries to the rescue, maybe

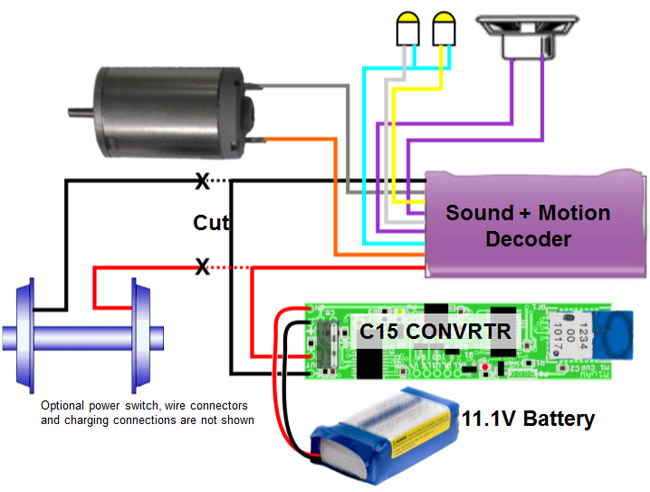

It turns out that the advances in battery technologies such as high-capacity yet light rechargeable lithium-based cells are not only offering new approaches for everything from portable devices and instrumentation to electric vehicles, they also are affecting the entire approach to powering the model railroad locomotives. Instead of providing this power via the obvious and available rails, in some cases, a set of batteries can be carried by the model train and used to power the locomotive. One commercially available unit for this is the AirWire900 Battery Powered Wireless DCC Control System, (Figure 1). This scheme not only eliminates the rails as power feeds but also the small brushes which pick up power from the wheels and transfer to the motor.

As in so many similar situations, it’s largely about physical space and weight. Since models of diesel locomotives have almost no spare room (it’s hard enough to fit the DCC decoder IC in there), this method is limited thus far to models of steam engines with their trailing tender, a convenient place to tuck the batteries, or to a dummy locomotive behind the powered one (it’s realistic because dual locomotives are often used for long freight trains in real railroads). In addition to the battery and its management circuitry, their arrangement also uses a wireless receiver also placed in the tender. The locomotive gets its DCC commands via the wireless link from the user’s controller.

Why bother with all this extra work and headache, given the inherently available physical arrangement? By going to on-board battery power instead of getting power via the convenient, already-in-place rails, all of the cited track and polarity problems just go away. Reliable rail connectivity and polarity reversals are no longer items to worry about because they have been literally designed out of the situation.

This is a case where the obvious, easy, low/no-cost method of delivering power to a load turns out to have many subtle and not-so-subtle implications in terms of basic reliability and operational issues. Modelers have learned to live with them quite successfully over the years, and it can be very reliable if you do it right and do regular inspection and maintenance.

Yet, it is a headache. The internal-battery approach is a nice alternative which avoids all these problems but is more costly (batteries, radio-control system) and has a limited run time of about an hour before you either swap or recharge the batteries. The biggest problem is finding a place for the battery and receiver. Much of the development work has been driven by those large outdoor-garden models’ needs since their weather-exposed tracks, leaves, and debris on the tracks and small shifts of the ground itself make delivering power through the rails a real challenge requiring constant maintenance and upkeep. These larger models do have space for batteries, so it’s a good fit.

Conclusion

Technologies such as networking and batteries have been adopted by such ordinary hobbies such as model railroading to solve long-standing problems. While there have been clever solutions to these problems over the years, each of these solutions has been cumbersome and complex, especially for the non-electrical engineer or someone not skilled in installing LEDs and phototransistors or leakage-current functions for block occupancy detection, or automatic power-switchover circuits. However, as with most such advances, the progress also brings additional complexity in setup and debugging compared to the earlier approach. Still, most users have judged the tradeoff to be worthwhile, just as a brand-new PC needs set-up and configuration, as well as regular updates, so you can take advantage of the efficiencies of using word processing or a spreadsheet.

This adoption is when the original applications of innovations are adapted to broader or unforeseen applications to solve other problems. Yet it is the true story of innovation versus predictions, as shown so clearly by James Burke in his insightful 10-part TV series “Connections” in 1978 – still insightful despite its age, and available online at YouTube and other sites.

EE World Related Content

- Electric locomotives and catenary power systems – Part 1: basic functions

- Electric locomotives and catenary power systems – Part 2: power needs

- Electric locomotives and catenary power systems – Part 3: power delivery

- Electric locomotives and catenary power systems – Part 4: maintenance and corona

- Westinghouse and the fail-safe train air brake, Part 1: The problem

- Westinghouse and the fail-safe train air brake, Part 2: The solution

- Westinghouse and the fail-safe train air brake, Part 3: Electric brake control

- Westinghouse and the fail-safe train air brake, Part 4: Post-Westinghouse

- Sorry, but it’s “Goodbye, Caboose” – EoT devices have made you obsolete, Part 1

- Sorry, but it’s “Goodbye, Caboose” – EoT devices have made you obsolete, Part 2

- Electrified Locomotives, Tunnels, and the Pennsylvania Railroad: Astonishing engineering but a partially sad ending, Part 1: The challenge

- Electrified Locomotives, Tunnels, and the Pennsylvania Railroad, Part 2: The tunnels

- Electrified Locomotives, Tunnels, and the Pennsylvania Railroad, Part 3: The station

Other References

- Model Railroader, “How to wire a layout for two-train operation”

- National Model Railroaders Association (NMRA), “Beginners guide to Command Control and DCC“

- Southern Digital, “How DCC Works”

- DCC Wiki, “DCC Tutorial — Basic System”

- CVPUSA, “The AirWire900™ Battery Powered Wireless DCC Control System”

- Wikipedia, “Connections” (TV series)