The speed at which a battery can be recharged is measured using the “C-rate,” where “C” is the battery’s capacity in mA or A. At a 1 C rate, a battery can be completely recharged in one hour. The speed of charge primarily depends on the voltage.

For example:

- For small batteries used in portable electronic devices, the C-rate of charging is based on the output voltage of the charger.

- For large battery packs, such as those used in electric vehicles (EVs), the C-rate of charging depends on the input and output voltages of the charger.

Let’s review the basic Li-ion charging for portable devices, look at the USB PD and Qualcomm Quick Charge technologies for faster charging of portable devices, and discuss the levels of EV charging including extreme fast-charging (XFC) technology.

The standard Li-on

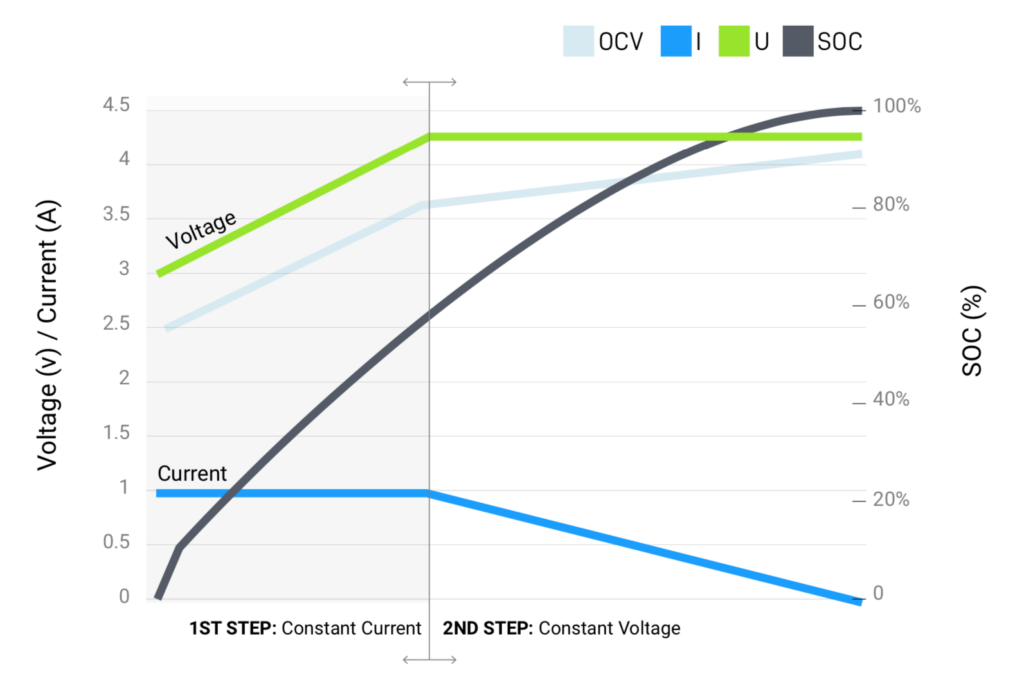

Charging a standard Li-ion is a two-step process, starting with constant-current (CC) charging and finishing with constant-voltage (CV) charging (Figure 1). CC charging is used to bring the voltage back to the end-of-charge level, which is the nominal voltage rating of the battery. At that point, CV charging takes over and the current flow slowly declines.

When the current reaches a low level, which is dependent on the specific battery chemistry, the charging stops, and the voltage is removed.

Figure 1: Correctly charging most Li-ion batteries involves two steps, CC followed by CV. (Image: Saft)

The optimal C rate for charging and end-of-charge voltage varies based on the chemistry being used and other factors, such as the temperature.

For example:

- Lithium Manganese Oxide: 0.7–1C typical, 3C maximum, 4.20V end-of-charge voltage

- Lithium Iron Phosphate: 0.3 typical, 1C maximum, 3.65V end-of-charge voltage

- Lithium Nickel Manganese Cobalt Oxide: 0.7 typical, 1C maximum, 4.20 to 4.30 V end-of-charge voltage, depending on the design

- Lithium Titanate: 1C typical, 5C maximum, 2.85V end-of-charge voltage

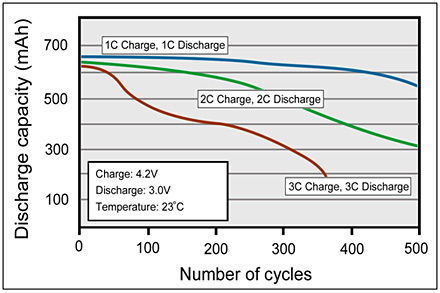

Charging Li-ion batteries at higher rates reduces cycle life (Figure 2). Slow charge rates of C/2, C/5, or less can result in slower battery aging and longer cycle life. Designers must compromise the time spent charging the battery with the time available for use in a given application.

In addition, reducing the end-of-charge voltage target by 100mV or more can extend the battery life by putting less stress on the electrodes — but at the expense of lower capacity. A battery’s capacity is directly dependent on the end-of-charge voltage. Lowering the voltage reduces battery capacity.

Figure 2: Li-ion batteries can be charged faster than a 1C rate with a reduction in cycle life. (Image: Battery University)

Float mode

Float mode is another consideration when charging Li-ions. It uses a permanent (low) current after the CV mode is completed. Float mode is sometimes used with energy applications, such as energy storage systems for photovoltaic panels. However, most Li-ion batteries are not designed for a float mode after reaching a fully charged state.

If it’s ideal for a given application, the batteries must be specifically designed to support float mode. Otherwise, a continuous charge current could result in overcharging, which can damage the cell and potentially lead to a fire or explosion.

Temperature

The temperature must be controlled when charging Li-ions. The graphite electrodes in most of these batteries can be damaged when charged at an elevated temperature, resulting in permanent capacity loss. High C rate charging can increase the capacity loss effect because high charging currents can increase the internal temperature of the battery. If a battery is subjected to a high voltage and a high temperature at the same time, outgassing can occur in the cell, resulting in swelling and other damage.

In addition, at lower temperatures, Li-ions charge more slowly. Few Li- can be charged below 0° C. Given the adverse effects of extreme temperature, it’s important to continuously monitor the battery during charging and slow or even stop it if the temperature rises or falls too much.

Faster charging

Faster charging requires higher voltages. So, the challenge here is to manage temperature rise. The original USB power specification was limited to 5V and up to 3A (depending on the implementation) for a maximum of 15W. The USB PD (power delivery) specification delivers multiple voltages — 5, 9, 15, and 20 V and up to 5A — for a maximum power of 100W and faster battery charging.

The USB PD PPS (programmable power supply) technology determines the charging status of a battery in real-time, adjusting the voltage and current to deliver maximum power while minimizing the temperature rise.

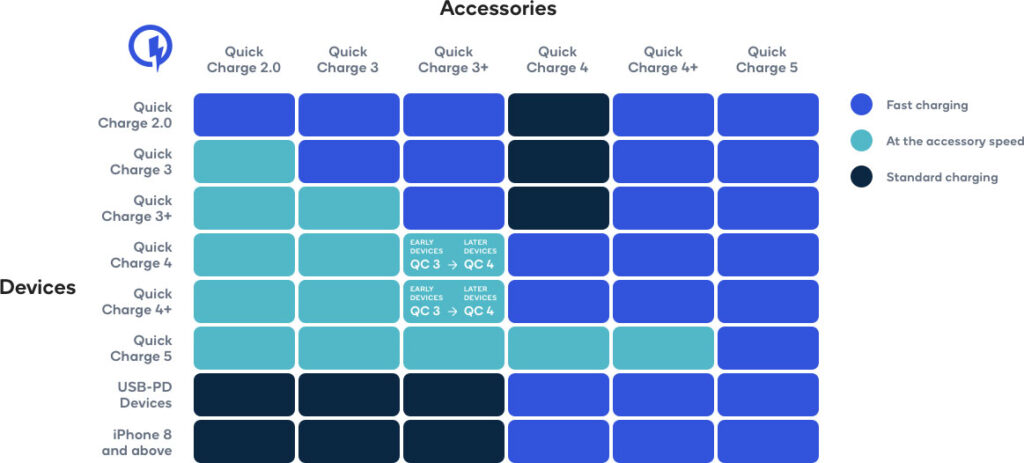

Qualcomm’s Quick Charge technology has evolved with a focus on temperature management. Quick Charge 2.0 added Dual Charge, which uses two power-management ICs (PMICs) in the handset to split the charging current into two streams. This reduces handset and, therefore, a rise in battery temperature.

In version 3.0, Quick Charge added Intelligent Negotiation for Optimal Voltage (INOV), Battery Saver Technologies, HVDCP+, and Dual Charge+. INOV determines the optimum power transfer to support maximum efficiency. Battery Saver Technologies optimizes charging to maintain at least 80% of the battery’s original charge capacity after 500 charge cycles.

Quick Charge 3.0 without Dual Charge+ is up to 6° C cooler, 16% faster, and 38% more efficient than Quick Charge 2.0, and Quick Charge 3.0 using Dual Charge+ is up to 8° C cooler, 27% faster and 45% more efficient than Quick Charge 2.0 with Dual Charge.

Quick Charge 4 added Dual Charge++ and is compatible with USB-C and USB PD. Additional safety measures were included to protect against overvoltage, overcurrent, overheating, and cable quality detection. Quick Charge 4 with Dual Charge++ is up to 5° C cooler, 20% faster, and 30% more efficient than Quick Charge 3.0 with Dual Charge+.

Dual Charge++ is mandatory with Quick Charge 4, though it was optional with earlier versions. Quick Charge 5 is compatible with USB-PD PPS and can charge a 4500 mAh battery in a mobile phone up to 50% in five minutes (Figure 3).

Figure 3: Qualcomm’s Quick Charge 5 is compatible with the USB-PD PPS (programmable power supply) specification. (Image: Qualcomm)

EVs are different

The batteries, battery packs, and battery management systems in EVs are different. The voltages of EV battery packs are high and getting higher — up to 800 V. Moving from 400 V used in most current EVs to 800 V can reduce charging times by 50%.

For example, some 800 V EVs can handle 200 kW of charging power and go from a 10 to 80% charge in 18 minutes. Twice the voltage means that smaller and lighter-weight cables can be used to deliver the same power. Lower current also results in less heat generation and lower temperature rises.

In addition to higher battery pack voltages, the speed of EV charging is related to the input voltage of the charger. In the U.S., SAE J1772 recognizes three charging levels:

- Level 1 uses 120 Vac input and is limited to about 1.9 kW, powering an onboard EV charger.

- Level 2 is called “fast AC charging” and uses 208/240 Vac single-phase power to supply up to about 19 kW with a 240 VAC source. It charges up to seven times faster than Level 1.

- Level 3 is DC fast charging and uses an external charger to deliver 240 kW using 600 Vdc and 400 A. Advanced designs can deliver 500 kW using 1,000 Vdc and 500 A.

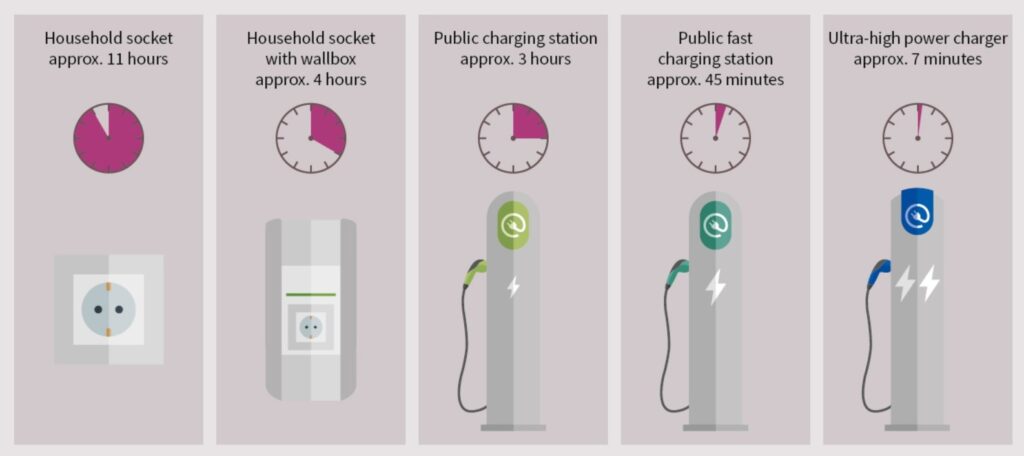

In Europe, IEC 61851-1 defines four modes of EV charging (Figure 4):

- Mode 1 charging is low power and uses a simple cable plugged directly into an AC outlet.

- Mode 2 adds integrated protection, called an in-cable control and protection device (IC-CPD). It plugs directly into an AC outlet. IC-CPD makes Mode 2, which is safer than Mode 1, but it’s still limited to about 15 kW with three-phase power.

- Mode 3 uses a dedicated charging station to deliver up to 120 kW AC. Modes 1, 2, and 3 all use the EV’s onboard charger to control battery charging.

- Mode 4 refers to fast DC charging. Several hundred kWs can be delivered with Mode 4. Energy feedback and charging control are possible in Mode 3, but they’re required in Mode 4. The latest version of Mode 4 is XFC, which can deliver up to 350 kW.

Figure 4: IEC 61851-1 defines four modes of EV charging, Mode 4 has been extended to support up to 350 kW called XFC. (Image: Infineon Technologies)

According to IEC 62196, the temperature at the contacts of the connector delivering charging power to the car cannot exceed 50° C. If the temperature rises above this level, the charger must slow or stop the charging. Active cooling of the cables and connector system is required in systems that deliver charging currents over 250 A.

Summary

The rate at which a battery or battery pack can be recharged is dependent on the voltage used and how effectively the battery can be managed given a rise in temperature. Most small batteries in portable devices are limited to 1C charging.

USB PD and Qualcomm Quick Charge technologies use combinations of finer voltage steps and more sensitive temperature monitoring to speed charge rates far beyond 1C. In some cases, they can charge a mobile phone battery to 50 percent in just five minutes. Charging EV batteries is more complex and involves multiple charging levels and charging modes to deliver power levels as high as 500 kW. In some newer designs, an EV battery pack can be charged to 80% in 18 minutes.

References

- Busting DC Fast Charging Myths, Chargepoint

- Charging your lithium-ion batteries: 5 expert tips for a longer lifespan, Saft

- Short charging time, long range – the e-car is getting off to a good start, Infineon Technologies

- Qualcomm Announces World’s Fastest Commercial Charging Solution, Quick Charge 5, Qualcomm

I want to make my tricycle electric. I have a 24v 500w motor. I am going to have a battery pack made up. I am wondering if I can use the motor as a dynamo to charge the battery pack when going downhill or will it be too much power and damage the batteries?

I don’t claim to be knowledgable in that field. That said, I don’t think you provided enough info to have a solid answer. Used as a generator, your motor will most likely provide less than 24V if it’s rated to run at 24V. You’ll most likely need a boost. given your output tension is hisgh enough, the charging capacity of your cells is based on their chemistry. If your battery pack is only cells in series (worst case senario, configuration 1P) and your motor provide 500W, you’ll charge at 20A. If you have LiFe chemistry, your battery pack consist of 7 cells in series. At 20A you would charge at roughly more than 4 times the maximum charging rate. That said, your pack would need to have at least 4 series of 7 cells in parallel to charge at the maximum rating of 1C and charge without damaging the battery.