An uninterruptible power supply or UPS is an electrical device that provides supplementary emergency power to the connected load when there’s a loss in the main power supply. It supplies power via a backup battery until the main power is restored. UPSs install between that regular power source and the load, with the supplied power passing through the UPS to get to the load. During a power failure, the UPS automatically and immediately senses the loss of incoming power from the main supply and switches outgoing power to come from the battery. This backup battery is typically designed to supply power for short periods — until power is restored.

UPSs commonly connect to critical components such as data and network devices that can’t afford to lose power. They are also used to ensure that connected loads, whether critical or not, continue to perform optimally in the case of a power failure. These devices help to prevent expensive downtime, tedious restart cycles, and data loss.

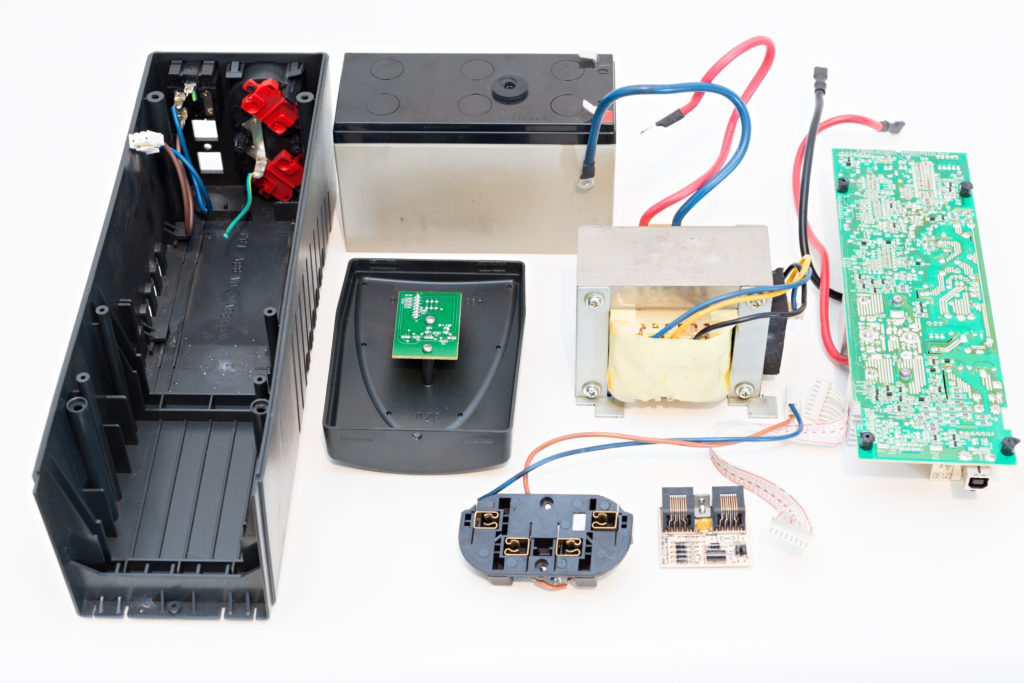

Although the name UPS is widely accepted as referring to a UPS system, a UPS is one component in a UPS system — albeit the main component. The whole system includes:

• The electronics that detect power losses and switch active output to draw from the battery

• The battery (whether lead acid or other) that provides the backup power

• Battery charger electronics that charge the battery.

Shown here is an all-in-one uninterrupted power supply or UPS with battery, charge electronics, charge-control electronics, and output receptacle.

UPS systems are supplied by manufacturers as all-in-one fully housed (and turnkey) components; UPS electronics and charger integrated into one product, but the battery sold separately; and totally separate UPS, battery, and battery-charger products. Fully integrated all-in-one components are most common in IT settings. UPS systems with UPS and charger electronics sans battery are most common in industrial settings such as factory floors. The third and least popular configuration is based on separately supplied UPS, battery, and battery charger.

UPSs are also categorized according to the power type (dc or ac) with which they’re compatible. All ac UPSs backup ac loads … and because backup battery is dc power, such UPSs can also backup dc loads. In contrast, dc UPSs can only backup dc-powered components.

How to use USPs to ensure optimal functionality

As mentioned, UPS systems are available for adding to dc and ac main power sources. It’s crucial to use the right UPS for the type of power in each application. Connecting ac power to a dc UPS can damage the component … and dc power is ineffective on ac UPSs. In addition, every UPS system has a power rating in wattage — the maximum amount of power that the UPS can supply. To provide adequate protection for the connected loads, the total power requirement of all the connected loads mustn’t surpass the UPS’s capacity. To properly size a UPS, calculate and sum the individual power ratings of all components requiring power backup. it’s recommended that engineers specify UPSs with a power rating that is at least 20% higher than the total calculated power requirement. Still other design considerations include …

Usage duration: UPS systems are designed to provide supplementary power and aren’t designed to be used for extended periods. UPS batteries are rated in Ampere-hours (Ah) specifying the battery’s capacity and its duration … so for example, a 20-Ah battery can supply anything from 1 A for 20 hours to 20 A for one hour. Always specify a UPS system with its battery duration in mind.

Maintenance personnel should understand that main power supply should be restored as soon as possible, and UPS batteries shouldn’t be subjected to being fully discharged. Otherwise, the backup battery could prove insufficient … and leave critical loads without any power at all. Minimizing the amount of time on a backup battery also extends that battery’s life.

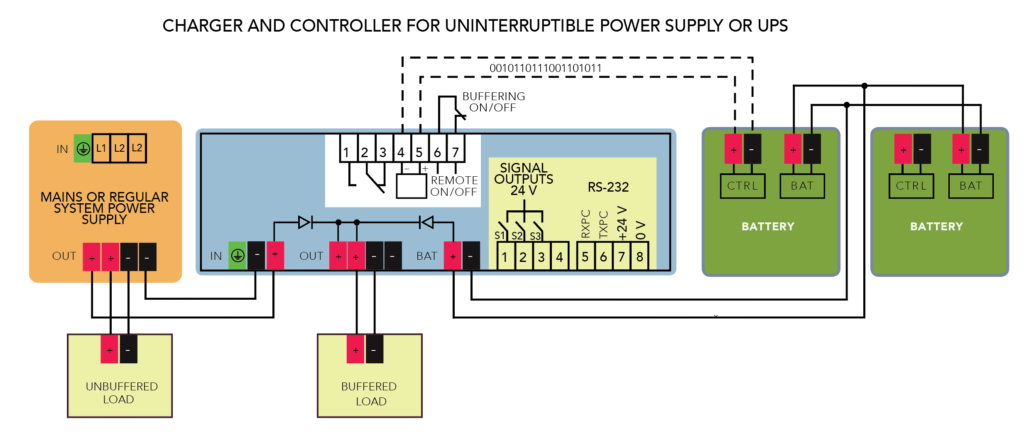

Compatibility: For optimal operation, the power supply, UPS, and connected loads must all be compatible. In addition, the voltage and amperage ratings of all three must match. This compatibility requirement also applies to all complementary wires and intermediary components (such as circuit breakers and fuses) in the system. The subcomponents within UPS systems (especially UPS control electronics and charger) built by system integrators or OEMs must also be compatible. Any such field-integrated designs should also be checked for proper wiring … including the connection of terminals and taking polarity into account.

Of course, the compatibility of subcomponents in fully integrated UPS systems is guaranteed as this is tested by the supplier during manufacturing and quality control.

Shown here is one example arrangement of how a UPS wires into a system.

Operating environment: UPSs are found in a wide array of typical to quite challenging environments. UPS manufacturers always specify the maximum and minimum operating temperatures at which a UPS system will function properly. Usage outside this specified range will lead to problems — including system malfunctions and damage to the battery. Manufacturers (with certifications, approvals, and class ratings) also specify UPS ability to withstand and operate in settings having various levels of humidity, pressure, airflow, altitude, and particulate matter.

Installation and operation: There are various manufacturer-specific installation and operation rules to follow to ensure UPS systems correctly function over their entire design life. There are also universal guidelines that apply to all UPSs.

• Installation must be carried out by qualified personnel only

• All power must be switched off during installment or disconnection

• To avoid electric shock and other hazards, don’t dismantle or electrically modify the UPS

• Inspect all connections to ensure that they are correctly done

• Installation and operations personnel should read the UPS installation manuals and product guides before installation and operation.

⚙️ Contribution by Etiido Uko • Mechanical engineer