The first FAQs in this series have identified specific use cases and applications where robots can use batteries, fuel cells, and even supercapacitors as their prime power source. Are there applications for robots that can benefit from using energy harvesting and ambient energy as their prime power source? Yes. For example, small nanorobots can use ambient energy sources; other powering options are often too large and heavy. And there’s lots of ambient energy available in the world’s oceans to power large autonomous ocean-going robot platforms.

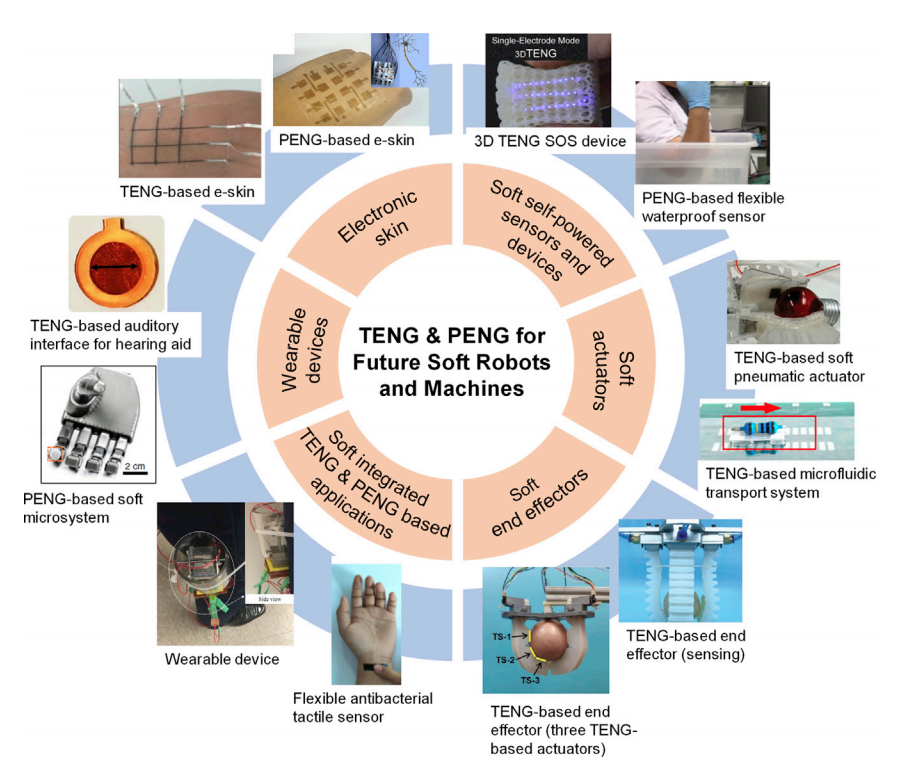

Small self-powered systems, including small robots currently under development, can use triboelectric nanogenerators (TENGs) and piezoelectric nanogenerators (PENGs) as prime power sources. With large open circuit voltages, low materials cost, ease of fabrication, and good energy conversion efficiencies, TENGs and PENGs are optimized for soft robotics use. Soft robots are fabricated with highly compliant materials with elastic moduli comparable to soft biological materials and tissues. For these soft robots to become practical, the sensing, actuation, and power systems need to be fully integrated both physically and operationally.

Soft robots are being developed for medical diagnostic, therapeutic, and rehabilitation applications. These robots often need specialized end effectors such as manipulators, robot hands, or grippers. Soft end effectors are desirable when interacting with soft or fragile elements. While TENG and PENG devices can provide the power levels needed for sensing and motion in soft robots, self-powered actuation using end effectors demands more energy. It can be challenging for TENG and PENG devices to power directly, and hybrid power systems may be required.

State-of-the-art TENG and PENG energy harvesting technologies and applications. (Image: iScience)

Today’s soft robots are typically on the scale of millimeters or centimeters, limiting the possible applications and enabling the use of TENG and PENG power sources. Many of these robots are targeted for use in small, confined, enclosed spaces, including vascular or intestinal tract for diagnostic, biomedical treatment, or drug delivery. These micro-scale soft robots may combine TENG and PENG power sources to maximize power generation and ensure power availability in various operating environments.

Electrostatic actuators and harvesters

In addition to TENGs and PENGs, electrostatic devices (ESDs) can harvest ambient energy in small robots. Like TENGs and PENGs, ESDs are easy to fabricate. ESDs can be used as artificial muscles, harvest energy, or pump for fluid-driven soft robots. These ESDs can produce flow rates of up to 0.63 liters per minute and a maximum pressure head of 6 kilopascals as a pump driver. When used as generators, they can reach conversion efficiencies close to 20%, similar to many photovoltaic devices. When designed to act as an artificial muscle, ESDs can lift loads over a hundred times their own weight, exert up to 6 Newtons of force and perform contractions of over 40% with a bandwidth of 10 Hertz.

In addition, ESDs can be designed so a single device is adaptable to various tasks such as linear actuators that contract on activation, hydrostatic pumps for fluidic actuators, and energy harvesting. Properly designed, these multi-purpose ESDs have demonstrated performance that is comparable to that of some single-purpose electrostatic actuators. In addition to being adaptable, ESDs are lightweight and scalable, making them highly suitable for soft robots. And to enhance peak power delivery, ESD-based energy harvesters can be used in combination with micro batteries.

Harvesting wave power for ocean-going robots

Self-powered ocean-going robots (unmanned surface vessels, USVs) can be handy for a variety of commercial uses, including environmental monitoring, tsunami, and seismic monitoring, fish and marine mammal monitoring, as well as defense applications such as anti-submarine warfare, surface vessel detection, and monitoring, over-the-horizon surveillance and communications gateways between submarines and surface vessels and satellites.

Wave energy and thermal differentials of water at varying depths are viable energy sources for large ocean-going robots with the potential to provide power for long-term deployments. Wave energy decreases with increasing depth. One specific ocean-going energy harvesting-powered robot platform called the Wave Glider uses a combination of wave energy harvesting and solar energy to power long-duration missions. The wave energy harvesting system on these platforms uses a two-part design that harvests the difference in wave energy at the surface versus the much lower energy available at a depth of 8 meters.

Wave Glider autonomous ocean-going robots use both wave energy harvesting and photovoltaic energy harvesting to power its operations. (Image: Liquid Robotics)

Stored solar energy is used to support enhanced operational capabilities. Solar energy is used to support an additional directional thrust to increase mobility and precision. It helps navigate challenging ocean conditions (doldrums, high currents, and hurricanes/cyclones), or accommodate mission changes. The solar energy system also recharges batteries that power sensors. Some of the operating specifications of the latest generation of Wave Glider robots include:

- Surface speed: 1.3kts, typical

- Endurance: Up to 1 year (varies based on operating conditions and location)

- Operating depth: 15+ meters

- Station keeping: 30m radius

- Payload capacity: 93 liters

- Tow capability: 500kg (drag dependent)

- Average continuous power: 5 to 20 Watts

- Solar energy: 192W, maximum

- Li-ion battery capacity: modular from 0.9kWh to 6.8kWh

- Communications: Satellite, Cell, and Wi-Fi

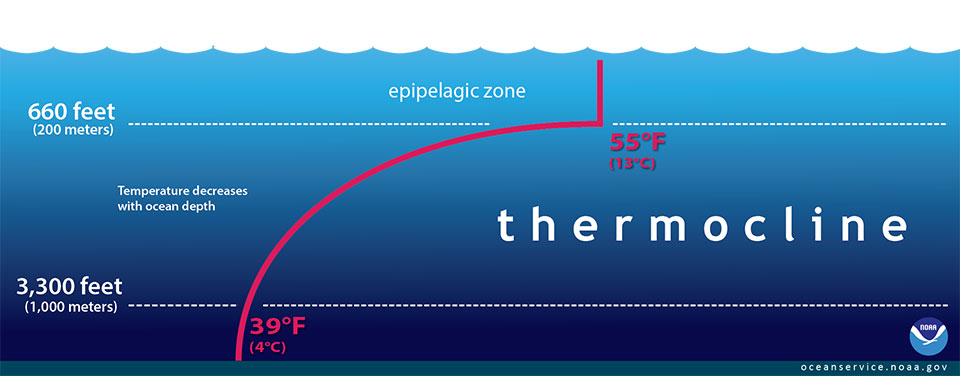

Harvesting energy from ocean thermoclines

A variety of thermal energy harvesting systems for unmanned undersea vehicles (UUVs) are being developed. In one instance, energy is being harvested from temperature differentials in the thermocline — a layer within the water column in which the temperature changes more rapidly than elsewhere. As the pod moves up and down a tether, it charges an internal battery.

The red line shows a typical seawater temperature profile. In the thermocline, temperature decreases rapidly from the mixed upper layer of the ocean (called the epipelagic zone) to much colder deep water in the thermocline (mesopelagic zone). (Image: National Oceanic and Atmospheric Administration)

Energy harvesting uses a phase-change material that captures temperature differentials throughout the thermocline. It harvests energy from the transition from solid to liquid and from liquid to gas. The energy is recovered, the material is “recharged” as it cools and returns to a solid. The energy harvesting system is designed in an underwater glider compatible form factor. It can be used on a purpose-built glider or as a modular retrofit attachment for existing gliders. It can operate down to 1,000 meters and can generate 20kJ of energy per cycle.

Phase-change energy harvesting system. During the warming phase (left) the contained working substance changes phase from solid to liquid, expands, and generates pressure that forces hydraulic oil through a generator to produce electrical energy. During the cooling phase (right) the working substance freezes and contracts. (Image: Seatrec)

Expansion of the phase-change material (PCM) results in pressure captured and used to generate electricity. Designs are being developed to generate energy from solid-to-liquid (SL) and liquid-to-gas (LG) phase transitions. For the solid-to-liquid (SL) example, when PCMs experience temperature changes, they undergo a phase transition and change volume. This volume change will drive a motor through pressurized fluid, converting hydraulic energy into electricity.

DARPA manta ray UUV

Unmanned undersea vehicles (UUVs) that operate for extended durations without the need for human logistic support or maintenance that offer the potential for persistent operations in forward military environments are of interest to the Defense Advanced Research Projects Agency (DARPA). These energy harvesting-powered UUVs could allow traditional host vessels increased freedom of operational flexibility and enhanced capabilities. Called the Manta Ray program, one of the main challenges is building a perpetual energy harvesting system that delivered adequate power for the autonomous submarine to operate indefinitely, potentially for a year or longer.

As currently envisioned, Manta Ray will use a combination of energy harvesting technologies, including thermoelectric power conversion (as the primary power source), “kites” to harvest wave energy, and possibly phase change or photovoltaic energy harvesting. The Manta Ray program seeks to demonstrate critical technologies for a new class of long duration, long-range, payload-capable UUVs. If successful, this new class of UUV will give the combatant commander an amplification of capacity without disrupting current operations by remaining independent of manned vessels and ports once deployed.

DARPA’s manta ray UUV will use energy harvesting to enable long-duration, long-range, payload carrying capabilities. (Image: Naval Technology)

The Manta Ray program is comprehensive and plans to advance numerous key technologies that will benefit future UUV designs, not just energy harvesting. Those technologies include:

- Low-power, high-efficiency undersea propulsion systems;

- New low-power means of underwater detection and classification of hazards or counter detection threats;

- Mission management approaches for extended durations while accounting for dynamic maritime environments;

- Unique approaches for leveraging existing maritime data sets and exploiting novel maritime parameters for high-efficiency navigation and/or command, communications, and control (3C);

- New approaches to mitigate biofouling, corrosion, and other material degradation for long-duration missions; and, of course

- Novel energy management techniques for UUV operations and undersea energy harvesting techniques at operationally relevant depths.

Summary

While they are not expected to power the majority of robots, various energy harvesting technologies can enable novel robot applications from nanobots for medical applications to large USVs and UUVs for various environmental monitoring and military missions. The field of robotics is broad and requires an equally broad selection of powering sources from rechargeable batteries, fuel cells, and supercapacitors to various energy harvesting technologies. This is the final FQA in the series. Earlier FAQs explored: “Battery options for mobile robots,” “Fuel cell-powered robot platforms,” and “Where do supercapacitors fit in robots?”

References

Autonomous Underwater Vehicle Thermoelectric Power Generation, University of Glasgow

Electrostatic bellow muscle actuators and energy harvesters that stack up, ScienceRobotics

Manta ray, DARPA

Triboelectric and Piezoelectric Nanogenerators for Future Soft Robots and Machines, iScience

What is a Thermocline?, National Oceanic and Atmospheric Administration

Tell Us What You Think!