Thermal runaway happens when a lithium-ion cell, or a small region within a cell, reaches a critical temperature where the materials start to undergo decomposition reactions. These reactions then generate significant additional heat. The decomposition reactions are temperature dependent, increasing exponentially as the temperature increases. Once decomposition starts, a chain reaction causes the battery to release its energy very rapidly, with explosive consequences.

Thermal runaway happens when a lithium-ion cell, or a small region within a cell, reaches a critical temperature where the materials start to undergo decomposition reactions. These reactions then generate significant additional heat. The decomposition reactions are temperature dependent, increasing exponentially as the temperature increases. Once decomposition starts, a chain reaction causes the battery to release its energy very rapidly, with explosive consequences.

The initial overheating can be caused by mechanical or thermal failures, overcharging or over-discharging, or an internal short circuit.

#1 Prevent cell-to-cell propagation

It may not be possible to eliminate the possibility of thermal runaway within a cell completely. While good thermal management, structural design, and battery management can reduce the risk, there is always the possibility of defects or foreign objects causing internal short circuits. Perhaps the most important mitigation is ensuring that a thermal runaway event will not cause cell-to-cell propagation in a battery module or pack. Although there are not yet standardized methods to prevent cell-to-cell propagation, important considerations include cell spacing, interstitial insulation, heatsinks, casing thickness, and venting features.

#2 Thermal management

The thermal management system in a battery module or pack should maintain a healthy operating temperature for cells under normal operating conditions to prevent degradation and thermal runaway. The thermal management system plays a vital role in managing potential thermal runaway events should they occur in an individual cell, ensuring they do not have serious consequences outside the battery and preventing cell-to-cell propagation. The safest approach is to assume that thermal runaway will occur in one of the cells at some point and then ensure that the resulting heat will have somewhere to go without causing runaway in an adjacent cell. Such an approach can be considered the gold standard in thermal runaway management, an approach developed by NASA.

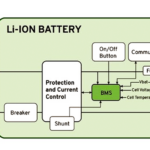

#3 Battery management

Good battery management should prevent electro-chemical abuse such as overcharging and over-discharging, reducing the risk of a thermal runaway as well as preserving battery condition. In addition to the pack-level battery management system, individual cells may be fitted with simple bimetallic switches which give an open circuit condition when a critical temperature is reached within the cell. These current interrupt devices (CID) may also be triggered by pressure as the cell cap deforms. A CID is often a single-use device, rendering a cell useless once triggered. Another issue with a CID is that a trigger can cause arcing, potentially initiating thermal runaway by igniting hydrocarbon vapor released from overheating electrolytes. A positive temperature coefficient thermistor (PTC) can be used similarly, producing a sudden increase in resistance when a specified temperature is reached. Most cylindrical cells have PTC thermistors. An issue with these devices is that they are located in the cell cap, while the hot spot where thermal runaway initiates may be deeper within the cell structure. Thermal fuses are another similar device.

#4 Structural design

Structural design of cells and battery packs can significantly reduce the risk of physical damage leading to internal short circuits.

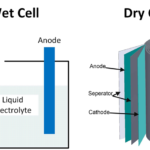

Methods of mitigating thermal runaway are continuing to be developed. It is essential to realize that no lithium-ion battery pack can be considered entirely immune from the risk of explosion – something true of fuel tanks. However, new cell materials not susceptible to thermal runaway are being developed. Solid state batteries could be completely immune to these risks without requiring heavy thermal management systems and protective cell spacing. In the future, battery packs could have much higher power density and lighter weight while eliminating the risk of thermal runaway.

Tell Us What You Think!