That depends. There is a wide range of regulations for lithium (Li) batteries. Some regulations, like those related to the transport of Li batteries and Li battery packs, have a broader impact than application-focused regulations like those for Li battery packs in electric vehicles (EVs) or industrial systems.

This FAQ begins by looking at three regulations related to the transport of Li batteries, pauses to briefly consider why those and other regulations are needed, then presents the rest of the list, and closes with a glance at the emerging “post-Li battery” era and how it may impact the sustainability and safety of energy storage systems.

UN/DOT 38.3 for safe transport of Li batteries. Li batteries are identified as a Class 9 dangerous good during transport and a potential fire hazard. UN/DOT 38.3 applies to all modes of transportation via air, sea, rail, or roadways. This regulation recognizes four classifications based on battery type, Li metal or Li-ion, and how they are shipped, separately or in a device:

- 3090 for lithium batteries and 3480 for lithium-ion batteries – Apply to cells shipped separately, including consignments of cells and batteries, incomplete battery sub-assemblies or modules, power banks, power packs, and other batteries, even if they are in the same consignment or shipment with the device they power.

- 3091 for lithium batteries and 3481 for lithium-ion batteries – Apply to batteries installed in devices. Consignments and shipments can include two spare batteries in addition to the battery installed in the device.

IEC 62281, Revision 4.1, February 2021, is like UN DOT 38.3 and applies to primary and secondary Li batteries but is more internationally recognized. UN DOT 38.3 is used mainly in the US IEC 62281 and includes the same tests as UN DOT 38.3 but adds a drop test. Section 7.3 lists exemptions, and IEC 62281 does not apply in some cases where special provisions are included in other regulations.

IATA Lithium Battery Shipping Regulations (LBSR), 2022 update. These regulations are based on the UN DOT and various IEC regulations related to Li batteries and have been adapted specifically for air transport.

Li batteries – what could go wrong?

While the transport regulations cover both primary and secondary Li batteries, Li-ion batteries (LIBs) can be particularly dangerous if not handled properly. Heat generation and buildup inside LIBs are the leading causes of safety incidents. Issues can occur due to LIB construction, system integration, and battery management software issues.

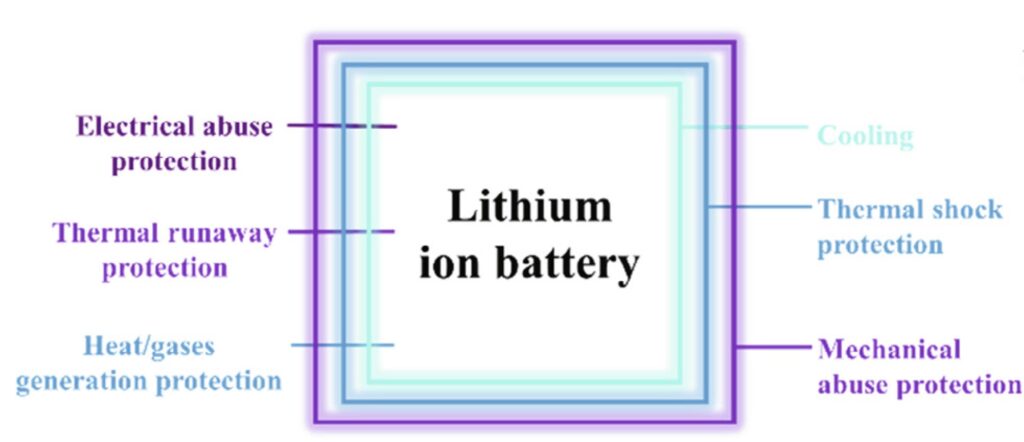

Thermal runaway in LIBs is not necessarily a quick process; it can occur in a matter of a few minutes but can also take days to unfold. It is defined in three stages beginning with the onset when the internal temperature rises above normal operational levels. If it’s not arrested in the first stage, exothermic reactions within the battery cause the internal temperature to continue rising linearly during the ramp stage. The final stage is thermal runaway, when the temperature rises rapidly, resulting in the destruction of the battery, usually accompanied by an aggressive fire and possibly an explosion. There are several strategies available to ensure LIB safety (Figure 1):

- Provision of adequate cooling, especially for batteries used in harsh environments.

- Protection from thermal shock.

- Protection from electrical abuse like overcharging and mechanical abuses like the penetration of a nail.

- Venting heat and gasses to prevent pressure buildup.

- Some form of thermal runaway protection like suppression or inerting systems.

Figure 1: Multiple approaches are needed to ensure safe operation of LIBs across all environmental and operating conditions. (Image: Journal of Energy Chemistry)

The rest of the list

IEC 62619:2022 relates to the use of secondary lithium cells and batteries used in two industrial categories:

- Stationary applications including telecom, uninterruptible power supplies (UPS), general energy storage systems, emergency and backup power, and similar applications.

- Motive applications including forklift trucks, golf carts, automated guided vehicles and autonomous robots, and railway and marine vehicles. It specifically excludes road vehicles.

IEC 62660-3:2022 – Secondary lithium-ion cells and batteries for propulsion electric road vehicles. Part 3 covers safety requirements, test procedures, and acceptance criteria for batteries in electric vehicles (EVs), including battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs).

UL 2580, Edition 3 Edition March 11, 2020, covers electrical energy storage assemblies, including battery packs and combination battery pack plus electrochemical capacitor (super capacitor) assemblies and the subassemblies that make up these assemblies for use in electric-powered vehicles. This standard does not include requirements for the evaluation of batteries for light electric vehicles like electric-assist bicycles, wheelchairs, electric scooters, etc.

UL 2271 for light electric vehicle (LEV) applications like electric bicycles, scooters, motorcycles, wheelchairs, golf carts, ride-on floor care machines, and lawnmowers. Testing includes overcharging, over-discharging, imbalanced charging of packs, and short circuits, all at maximum specified temperature. Mechanical tests include crushing, drops, vibration, shock, and rollover. Environmental testing includes exposure to the stated ingress protection (IP) rating for the pack, immersion (if appropriate), and rapid thermal cycling from extreme hot to extreme cold and back to extreme hot. It considers all battery components. Certification requires that the batteries don’t leak electrolytes, rupture, catch fire, explode, present an electric shock hazard or lose any protective features.

UL 1642 covers many applications like pacemakers, electronic medical devices, toys, clocks, cameras, and oceanographic instruments. It includes guidelines that set a limit on the amount of lithium for rechargeable or non-rechargeable batteries and individual cells in two use cases:

- If the battery is “technician-replaceable”, the battery can contain a maximum of 5.0 grams of metallic lithium

- If the battery is “user-replaceable”, each battery can contain a maximum of 4.0 grams of metallic lithium, and each cell should contain a maximum 1.0 grams of metallic lithium

UL 62133 / IEC 62133 / EC 62133-2:2017+AMD1:2021 CSV address lithium batteries in portable systems. UN 38.3 transportation testing is an integral requirement but does not need to be repeated. Four tests are included:

- Molded case stress

- External short circuit

- Free fall

- Overcharging

Figure 2: Depending on the application, portable and mobile LIB battery packs must meet different standards. (Image: UL)

UL 2054, 3rd edition, 2021 for household and commercial batteries is mandated by several end device standards. It includes about double the number of tests found in corresponding UN or IEC standards, including:

- 1 fire exposure test

- 2 environmental tests

- 4 mechanical tests

- 4 battery enclosure tests

- 7 electrical tests

What about the future?

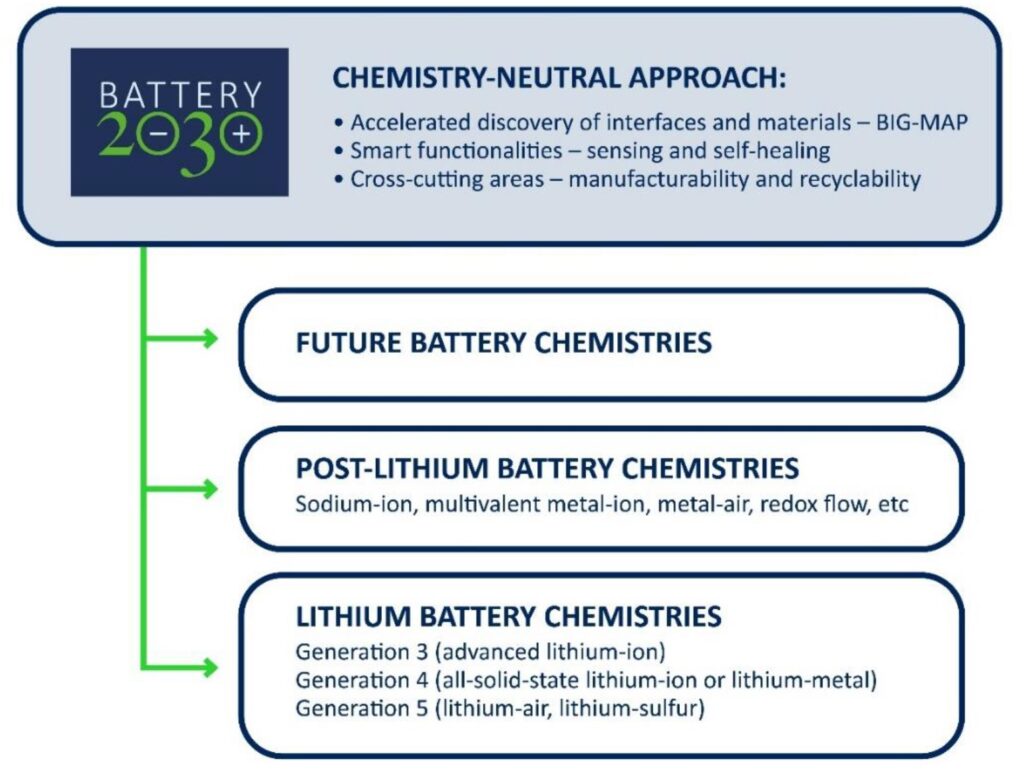

LIBs continue to improve slowly in performance but are a mature technology. Worldwide efforts are underway to determine what comes after LIBs, the so-called post-lithium batteries. Sustainability and safety are two constant requirements that LIB replacements will have to address. Proposed chemistries like sodium-ion batteries (NIBs), potassium-ion batteries (PIBs), and other chemistries are being pursued. If the performance of those batteries can match that of LIBs, they will offer inherently safe chemistries and completely change the battery safety regulation landscape.

For example, the European Union’s Battery 2030+ program strives to invent the future’s sustainable batteries. The Battery 2030+ is a chemistry-neutral effort to develop safe, sustainable, and cost-effective rechargeable technologies for various applications.

The Battery 2030+ roadmap includes three major research themes, each with two areas of focus:

- Accelerated discovery of battery interfaces and materials

- Battery interface genome

- Materials acceleration platform

- Integration of smart functionalities

- Sensing

- Self-healing

- Cross-cutting areas

- Manufacturability

- Recyclability

Figure 3: The EU’s Battery 2030+ effort is focused on developing advanced LIBs, today’s post-lithium chemistries, and advanced chemistries for the future. (Image: Battery 2030+)

Summary

A wide range of IEC, UL, and other standards govern the safety of primary and secondary lithium batteries. The basic standards for the transpiration of the batteries relate to almost all applications. The primary concern in most cases is the prevention of thermal runaway that can result in fires or explosions. While that’s the single underlying concern, a range of standards has been developed to address the needs of specific applications and operating environments. If development efforts related to NIBs, PIBs, or other advanced chemistries are successful, the need for safety standards could be significantly reduced.

References

A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards, Journal of Energy Chemistry

Batteries Are Everywhere. Safety Should Be, Too., UL

Battery 2030+ Roadmap, European Union

Lithium Battery Guide for Shippers, US Department of Transportation

UN 38.3 Certification for Lithium Batteries, Intertek

Tell Us What You Think!