Expansion of grid-scale energy storage is important to enable the transition to variable renewable energy (VRE) sources such as wind and solar, and a green energy economy. The use of battery energy storage systems (BESS) is a key to enabling the growing penetration of VREs. BESS installations are classified as behind-the-meter (BTM) or front of the meter (FTM). BTM BESS installations are found in commercial, industrial, and residential buildings to support demand-side management. FTM installations are connected to transmission or distribution networks to integrate VREs efficiently.

This FAQ looks at some of the technology and economic challenges associated with FTM BESS installations and some emerging energy storage technologies that may be able to address those challenges.

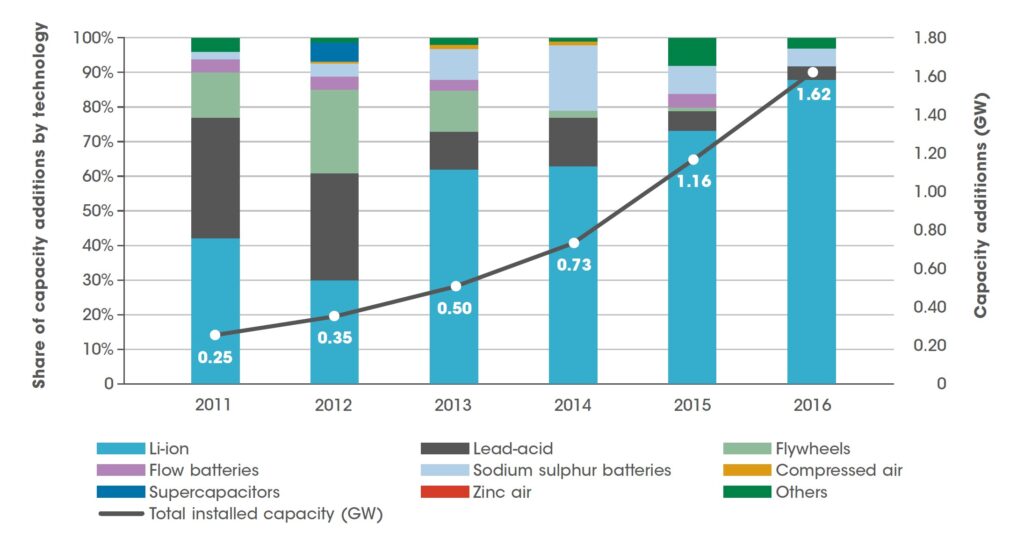

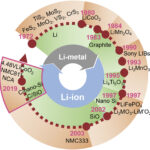

Li-ion batteries currently dominate the grid-scale BESSs needed to support FTM installations (Figure 1). In the longer term, that is not expected to be sustainable. Until recently, the expanding share of Li-ion in grid-scale BESSs was being driven by declining costs for Li-ion batteries. That trend is expected to reverse as demand for Li-ion batteries spikes due to mandates to switch to electric vehicles that take effect later this decade. As a result, there’s a growing awareness of the need to develop alternative technologies to support grid-scale FTM BESS installations.

Figure 1: Li-ion batteries have long dominated grid-scale energy storage installations. (Image: International Renewable Energy Agency)

Large-scale energy storage makes equally large demands on batteries. The EU has established the Strategic Energy Technology (SET) plan to enable the widespread use of VRE. As part of SET, goals have been established for the cost (0.05 € kW-1 h-1 cycle-1) and durability (10,000 cycles and 20 years lifetime) to be achieved by 2030. Other key characteristics of battery storage systems include:

- High power density, defined as the total possible instantaneous discharge capability, in kW or MW, or the maximum rate of power the BESS can deliver when fully charged.

- High energy density in terms of kWh or MWh to support extended operation. For example, a BESS with a 1 MW power capacity and 4 MWh of energy capacity has a storage duration of four hours.

- Long cycle life is important for the BESS to provide regular charging and discharging before failure or significant degradation. However, installation and maintenance costs are still the main barriers to the penetration of storage on the grid.

- Low self-discharge enables energy to be stored for long periods and is especially important for batteries intended for longer-duration applications.

- High round-trip efficiency, measured as a percentage of the energy-charged delivered into the battery to the energy discharged from the battery, including losses from self-discharge and other electrical inefficiencies. This is an area of differences; battery manufacturers often refer to the DC-DC efficiency of energy flow into and out of the battery. For utilities, AC-AC efficiency is more important (and lower than DC-DC efficiency), as they consider efficiency from the point of interconnection to the power system, which uses AC

Sodium-sulfur

Sodium-sulfur (NaS) batteries are Li-ion alternative that offers several performance capabilities needed for VRE BESSs. NaS is a molten-salt battery made using non-toxic and low-cost materials and combines high energy density (5 times that of lead-acid) and high efficiency of charge/discharge. NaS batteries are available that are rated for 15-year operation.

NaS cells are usually steel cylinders with a chromium or molybdenum lining to provide corrosion protection. The steel cylinder is the positive electrode, and the liquid sodium is the negative electrode. A beta-alumina solid electrolyte (BASE) membrane separates the liquid Na and liquid S and conducts the Na+ ions that form the basis of the electrochemical system that operates at 350 °C.

High-temperature operation combined with the highly corrosive nature of the reactants makes NaS batteries unsuited for portable applications. When used in stationary BESS installations, NaS technology becomes more cost-effective as the size of the cells increases. Commercially available cells can be large, with capacities up to 500Ah. Larger cells cool slower, making it easier to maintain the needed 350 °C operating environments. The cells are installed in blocks in a BESS and encased in a vacuum-insulated box for better thermal management.

Sodium Iodide

Sodium-iodide (NaI) batteries are being developed to address the high-temperature operation required by NaS technology. While a NaS battery operates at 350 °C, a NaI cell operates at only 110 °C. the lower operating temperature enables less expensive materials and less insulation. And, with a nominal voltage of 3.6 volts, a NaI battery has a 40% higher operating voltage than a NaS battery, resulting in a higher energy density. Higher energy density means that to deliver a given energy level, a NaI-based BESS would need fewer cells than a NaS BESS. Fewer cells should reduce costs and also lead to fewer interconnections, contributing to higher efficiency and improved reliability.

However, while NaS batteries have been commercialized, NaI is still under development. Dropping the temperature from 350 °C to 110 °C requires using a different materials structure. Instead of a cathode made from elemental sulfur, a NaI battery has a new structure called a catholyte, a mixture of the salts sodium iodide and gallium chloride (GaCl3). When a NaI battery discharges, the liquid Na produces Na+ ions that move through a ceramic separator, similar to the BASE in the NaS battery and react with iodine ions to form molten sodium iodide salt.

The key to the eventual commercialization of NaI batteries will be to refine the electrochemical system, especially the catholyte. The search is underway for a replacement for the GaCl3 since it’s very expensive, 100X the cost of NaCl, and makes these batteries uneconomical.

Iron energy storage

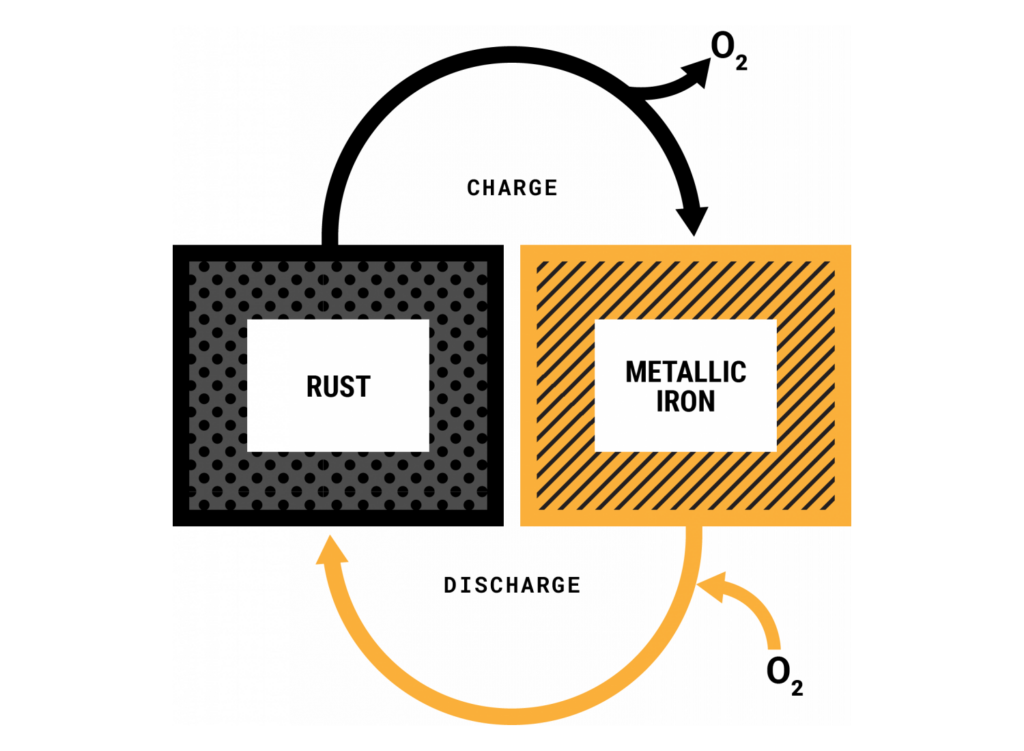

Iron (Fe) promises to deliver the lowest-cost grid-scale BESS designs, about one-tenth of a comparable Li-ion installation cost. First-generation Fe-air technology has been optimized to store electricity for 100 hours at system costs competitive with legacy power plants. Fe-air (iron-air) batteries are being perfected with operation based on ‘reversible oxidation’ (Figure 2). In discharge mode, thousands of tiny iron pellets are exposed to the oxygen in the air turning to iron oxide (rust). When the system is charged with an electric current, the oxygen in the rust is removed, and it’s converted back to elemental Fe. By using oxygen from the atmosphere, these batteries deliver good power density, and they are inherently safe due to the use of a water-based, non-flammable electrolyte.

Figure 2: Iron-air rechargeable batteries could deliver >3MW/acre of grid-scale energy storage. (Image: Form Energy)

Current Fe-air modules are cubes 1 meter on a side and contain 10 to 20 stacked 1-meter-square Fe-air cells. These battery modules are assembled in containers, and the containers are linked to building MW-scale BESSs. The configuration is flexible, and a 1 MW installation can range in size from 1 to 3 acres. Even higher density configurations are envisioned for the future. There is currently a 300MW ‘pilot’ project being built for Minnesota-based Great River Energy that will be commissioned in 2023. Commercialization of grid-scale Fe-air batteries is anticipated for later this decade.

Decoupling power and energy

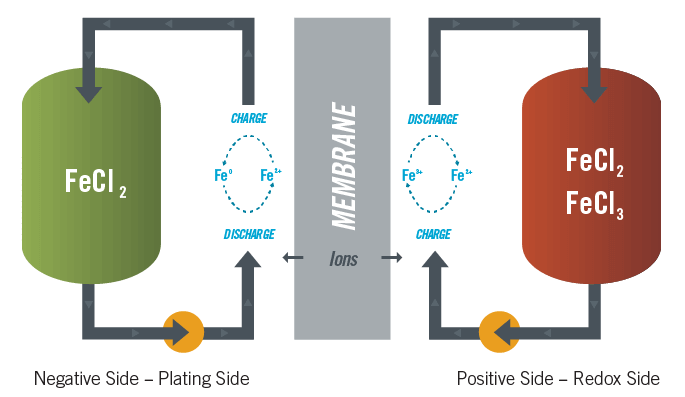

In addition to Fe-air batteries, iron can be used in a redox flow battery to decouple the power and energy performance of a BESS. A redox flow battery consists of three main elements; energy storage tanks, a stack of electrochemical cells, and the flow system (Figure 3). The size of the electrochemical stack determines the system’s power capability, and the amount of electrolyte stored in the tanks determines the total energy and runtime.

Figure 3: Flow batteries can be made based on various metal-based chemistries, including iron chlorides. (Image: Atladyn Energy Solutions)

Figure 3: Flow batteries can be made based on various metal-based chemistries, including iron chlorides. (Image: Atladyn Energy Solutions)

Vanadium redox flow batteries represent the current state-of-the-art for flow battery technology. But the recent development of iron flow batteries based on iron chlorides may significantly reduce the cost of flow batteries and open up new applications. Flow batteries generally enjoy high round trip energy efficiency and fast responsiveness. Currently available Fe flow battery modules have an energy storage capacity of 400 kWh, a 25-year design life, and can be configured to provide storage durations of 4 to 12 hours.

Summary

Grid-scale energy storage will be necessary to support the anticipated widespread deployment of VRE technologies such as solar and wind energy. Li-ion is currently the most widely-used energy storage technology in grid-scale BESSs. Still, the anticipated growth of demand for EV batteries coupled with the growth of VREs will make Li-ions increasingly expensive in the near future. The development of new energy storage options such as NaS, NaI, and Fe-air rechargeable batteries and Fe-chloride flow batteries will provide cost-effective and environmentally friendly options to Li-ions in future generations of grid-scale BESSs.

References

Enabling a 100% renewable grid, Form Energy

ESS iron flow chemistry, ESS, Inc.

Grid-Scale Battery Storage, National Renewable Energy Laboratory

Redox flow batteries: Status and perspective towards sustainable stationary energy storage, Journal of Power Sources

Sandia designs better batteries for grid-scale energy storage, Sandia National Laboratories

Utility-scale batteries, innovation landscape brief, International Renewable Energy Agency

Tell Us What You Think!