Energy harvesting (EH) can be an attractive way to power wireless internet of things (IoT) and other small devices. EH can be combined with rechargeable batteries, capacitors, or supercapacitors to provide enhanced performance. Depending on the circumstances, primary batteries can provide a more reliable and even lower-cost option. This FAQ looks at ways to classify EH sources, considers the advantages and drawbacks of EH, presents long-life primary batteries as an alternative to EH, and closes by reviewing the challenges associated with powering high-pulse power loads like remote actuators and data-intensive two-way radio communications.

What EH to use?

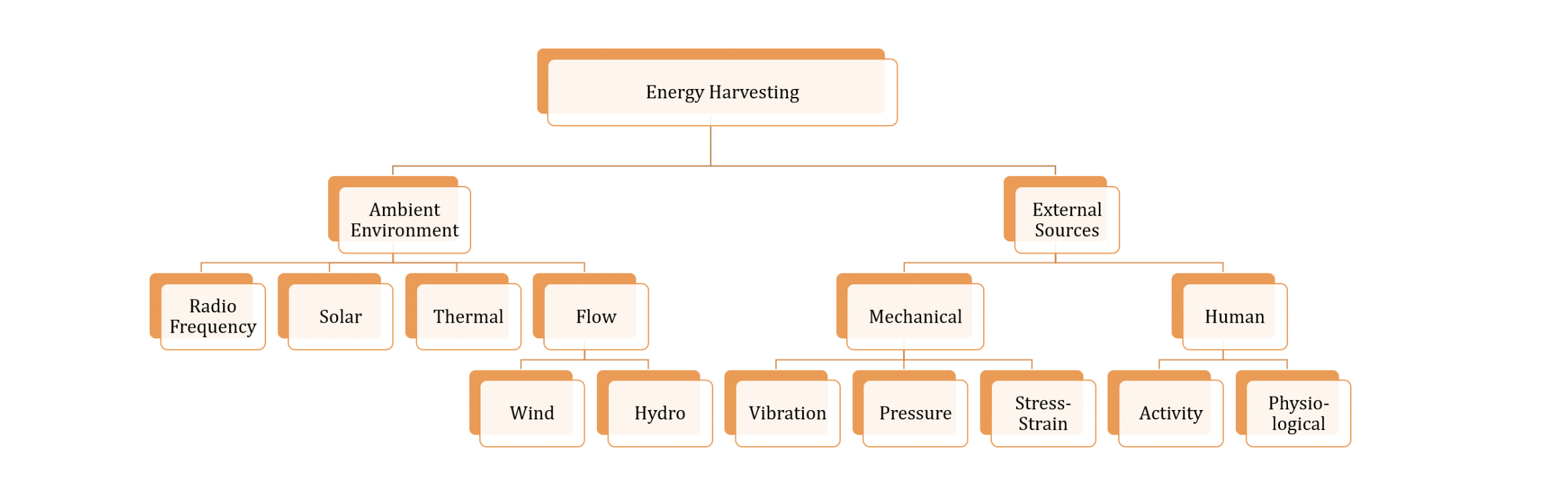

The energy source, or type of EH, is an important factor that determines availability, reliability, and cost. EH devices can derive their power from external or ambient energy sources (Figure 1). Artificial energy such as machine vibrations, heat, or pressures from manufacturing operations and human activities, are all external sources. Ambient energy sources include naturally occurring energy like wind, solar, and so on. The type of EH has important implications for energy availability, reliability, and cost.

Figure 1. EH technologies can be classified by whether the source of energy is from the ambient environment or an external source (Image: Nanoprecise).

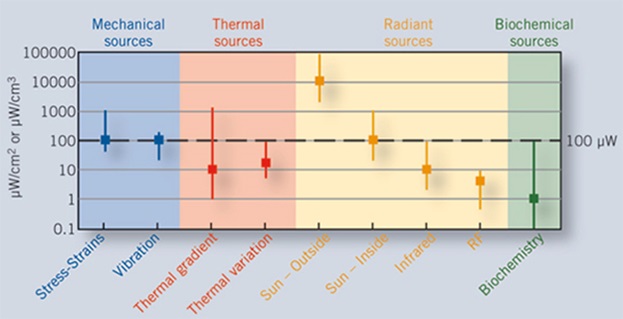

With few exceptions, like bright sunlight for higher power or ambient RF energy for low power, the sweet spot for EH applications lie in the microwatts (µW) to milliwatts (mW) power range, with typical energy densities of about 100 µW/cm2 (Figure 2). As a starting point for EH versus battery comparisons, consider a common CR2032 lithium manganese dioxide (LiMn02) non-rechargeable coin cell. It has a nominal voltage of 3.0 V, a capacity of about 235 mAh, and can provide 1 mW for only about 2 days, but if the power demand drops to the µW level, that same coin cell can last 4 years. Quite a difference. For very low-power applications with limited operating lifetimes coin cells can provide a lower-cost alternative to EH.

Figure 2. EH can be best suited for applications that consume microwatts to a few milliwatts of power (Image: Force Technology).

Another factor is that EH is not generally the most compact solution. This is an area where physics often conspires against EH. EH systems must accommodate a combination of low densities of available energy and low conversion efficiencies. As a result, providing significant amounts of power from thermal, vibration, and other sources of ambient energy can require a bulky solution compared to a battery.

EH is not free

EH sources are freely available, but EH systems are not free. In fact, they can cost more than battery power. Determining when to use EH and when to use batteries requires detailed and thoughtful analysis.

Specifying a battery power source is a straightforward exercise in analyzing system power requirements. Not so for EH, where analyzing system power needs is only the first step. Designing an EH source requires that the source be thoroughly analyzed in the actual operating environment, including any changes anticipated for that environment during the operating life of the powered device. The peak power capability of the EH device will often not be realized in actual installations. It can be necessary to develop a detailed model or database of the anticipated available energy levels over time. How reliable will it be? How will the conversion efficiency of the EH device vary as it ages or for differing available energy levels? What are the power management needs?

Power management

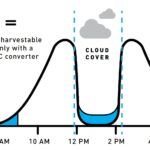

Power management needs can be the differentiator between using a battery or an EH power source. Power management for a battery-powered system can be a simple regulator to account for any voltage variations (usually declining voltage) as the battery is discharged. Power management for an EH system is more complex and potentially more costly. EH devices often require maximum power point tracking to produce the maximum output. Energy storage devices in a solar EH system can also require overcharge protection due to the unpredictability of solar energy.

For systems with peak load needs, what type of energy storage will be required? What charge management is required? The initial hardware and design cost for an EH system can be much larger than a battery-powered solution. For example, if multiple supercapacitors are used for energy storage, they require additional cell balancing circuits further increasing system size, weight, cost, and consumption of valuable energy.

On the other side of the equation, battery replacement costs need to be factored into the comparison. Battery replacement can be minimized by using a larger battery or a more environmentally rugged battery. Both options come with increased costs.

Energy storage device tradeoffs

Li-ion rechargeable batteries offer a combination of good energy density and environmental ruggedness that makes them suited for pairing with EH devices (Figure 3). Lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NAC) rechargeable chemistries offer nominal voltages of about 3.6 V and can be recharged 1,000 or more times. Supercapacitors can provide higher power densities compared to Li-ions and can be suitable for EH support in applications that require thousands or tens of thousands of charge and discharge cycles.

Figure 3. The energy densities of battery chemistries can vary by up to 100x (Image: ResearchGate).

EH is usually associated with rechargeable energy storage like Li-ion batteries and supercapacitors, but it can also be used with primary batteries. If an application needs infrequent pulses of power and needs a long operational life, primary batteries can be paired with EH. The EH together with a small capacitor can provide continuous levels of power for sensors or housekeeping, and a primary lithium battery can provide peak power needs and support long operational life.

Primary batteries are tried and true

Compared with EH choices which are mostly niche technologies, primary batteries are a mainstream option. Lithium-thionyl chloride (Li-SOCl2, or LTC) is particularly well suited for use as a long-term power source for wireless IoT nodes. Bobbin-style LTC batteries offer an operating temperature range from -40 to +85 °C, high capacities, an operating voltage of 3.6 V, and very low self-discharge rates, making them particularly suitable for providing long-term (20 years or longer) power for wireless IoT nodes. Some battery makers can provide data on self-discharge rates over various temperatures, pulse power capabilities, and other data needed to determine a battery’s operating life for a specific design, like the example in Table 1 below.

Table 1. Design example of a 20-year life from a AA-sized LTC battery for a wireless IoT node (Table source: Tadiran Batteries).

Power pulses and transient minimum voltage

Industrial IoT (IIoT) devices can also require high-power pulses of several amps. Higher than can be delivered by a standard LTC battery. The challenge with using a bobbin-style LTC battery to deliver high pulses is the temporary drop in the voltage delivered by the battery. The voltage returns to its nominal value after experiencing a transient minimum voltage (TMV) that can disrupt system operation. That can be addressed by using a spiral-type LTC battery that can deliver higher power pulses but at the cost of lower capacity and shorter operating life.

A hybrid device can be used that combines a bobbin-style LTC battery with a hybrid layer capacitor (HLC). The battery delivers the high capacity needed to support long operating life. The HLC can support periodic high-power pulses for functions like actuators or longer-distance two-way RF communications. The voltage curve of the hybrid device experiences a plateau near the end of life that can be monitored by the system and used to issue a low battery alert.

An alternative way to address TMV is to use supercapacitors. Supercapacitors tend to have limited temperature ranges making them less suitable for industrial applications or remote wireless IIoT nodes and are bulky with high self-discharge rates. When adding any capacitor in parallel to a battery, it’s important to consider the combined self-discharge of the battery and capacitor system. While supercapacitors have high rates of self-discharge, the HLC can be designed with a low rate of self-discharge, matching the self-discharge rate of the LTC battery and producing a long-life hybrid energy storage device.

Summary

EH can be an effective power source in a range of niche applications that either require very low levels of power or can accommodate a large and inefficient power source. While the ambient energy to be harvested can be free, an EH system entails significant upfront costs in terms of design and installation. In many mainstream applications, long-life primary batteries can provide a cost-effective and compact alternative to EH.

References

Batteryless Electronics, Force Technology

Energy Harvesting for IOT – Status and Evaluation, Nanoprecise

Lithium Batteries for Wireless Sensor Networks, Tadiran Batteries

Next-Generation IoT Devices: Sustainable Eco-Friendly Manufacturing, Energy Harvesting, and Wireless Connectivity, IEEE Journal of Microwaves

Power Versus Energy When Designing Smart Wireless Devices, International Society of Automation

Tell Us What You Think!