Advanced lithium battery technology delivers long-life power and high pulses to expand remote wireless connectivity throughout the Industrial Internet of Things.

Sol Jacobs | Tadiran Batteries

The Industrial Internet of Things (IIoT) is largely influenced by advanced wireless devices and sensors. To a large extent, the rapid expansion of industrial connectivity is being driven by industrial-grade batteries that deliver reliable power to remote locations and extreme environments.

Industrial grade Li-ion batteries can operate for up to 20 years and deliver 5,000 full recharge cycles. They also feature an expanded temperature range of -40 to 85°C and the ability to deliver high pulses.

For example, the typical oilfield is now equipped with 30,000 sensors. Having to hard-wire all these sensors would be time-consuming and prohibitively expensive. In addition, many of these sensors interface with the HART (Highway Addressable Remote Transducer) protocol, the traditional industry standard platform that adapts decades-old analog telephone caller ID using 4-20-mA analog wiring. Unfortunately, most HART-enabled devices were never fully integrated, largely for financial reasons, as it costs roughly $100/ft. to install any type of hard-wired device, even a basic electrical switch.

In remote locations and extreme environments, the costs associated with hard-wiring grows exponentially because of added expenses, including labor and materials, travel, and regulatory/permitting requirements. If all 30,000 wireless sensors in an oilfield connected via WirelessHART, all these cost barriers would disappear.

Each wireless application is unique, so different batteries are best for different applications. If a remote wireless device requires long operating life and only draws microamps daily, it will likely be powered by an industrial-grade primary (non-rechargeable) lithium battery. Conversely, if the device draws enough average daily current to exhaust a primary battery in short order, it may be better suited for an energy harvesting device feeding its harvested energy to a Lithium-ion (Li-ion) rechargeable battery.

Remote industrial wireless applications that require long-term deployment in hard-to-reach places or extreme environments typically cannot use consumer grade batteries. For example, because of their high self-discharge, alkaline batteries often last for only two or three years. Alkaline batteries also use a water-based chemistry that is prone to freezing, making them best suited for use indoors in moderate temperatures where they can easily be replaced.

The low initial purchase price of a consumer-grade battery can also be misleading. It does not reflect the true long-term cost of ownership which must account for all the costs of frequent battery replacements. These costs include that of the batteries themselves, ongoing labor costs, and the potential for system downtime and loss of data.

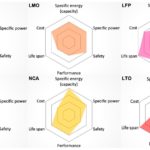

Here’s how primary lithium cells stack up in terms of performance qualities.

The selection of an industrial grade battery can be a complex process involving numerous technical considerations that include: energy consumed in active mode (including the size, duration, and frequency of pulses); energy consumed in ‘stand-by’ mode (the base current); storage time (as normal self-discharge during storage diminishes capacity); thermal environments (including storage and in-field operation); equipment cut-off voltage (as battery capacity is exhausted, or in extreme temperatures, voltage can drop to a point too low for the sensor to operate); battery self-discharge rate (which can be higher than the current drawn from average daily use);

and cost.

Here’s how industrial and consumer-oriented lithium cells distinguish themselves.

Other key considerations include battery reliability. Is the remote sensor in an inaccessible spot where battery replacement is difficult or impossible? Is loss of data due to battery failure not an option? And does the self-discharge rate of the battery exceed the energy lost through average daily consumption? If so, initial battery capacity must be as high as possible.

Size and environment can be considerations as well. If miniaturization is required, batteries with higher capacity and energy density pack more energy into a smaller footprint. If batteries with higher voltage can be specified, it may be possible to outfit the application with fewer cells. And if the device will see extremely hot or cold temperatures, the battery must be chosen to handle the range.

Finally, lifetime costs are a factor. Future costs to consider include labor and materials to replace batteries, and the possible risks associated with battery failure.

Primary lithium batteries

Lithium battery chemistry is widely preferred for long-term deployments thanks to its high intrinsic negative potential, which exceeds that of all other metals. As the lightest non-gaseous metal, lithium offers the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of all available battery chemistries. Lithium cells operate within a normal operating current voltage (OCV) range of 2.7 to 3.6 V. The absence of water also allows lithium batteries to endure extreme temperatures without freezing.

Numerous primary lithium chemistries are commercially available, including iron disulfate (LiFeS2), lithium manganese dioxide (LiMNO2), lithium thionyl chloride (LiSOCl2), and lithium metal oxide chemistry.

Lithium iron disulfate (LiFeS2) cells are relatively inexpensive, used mainly to deliver high pulses required to power a camera flash. LiFeS2 batteries have performance limitations that include a narrow temperature range (-20 to 60°C), a high annual self-discharge rate, and crimped seals that may leak.

Lithium Manganese Dioxide (LiMNO2) cells, including the widely used CR123A, provide a space-saving power source for cameras and toys, as one 3-V LiMNO2 cell can replace two 1.5-V alkaline cells. LiMNO2 batteries can deliver moderate pulses but suffer from low initial voltage, a narrow temperature range, a high self-discharge rate, and have crimped seals.

Specially modified bobbin-type LiSOCl2 batteries can be specially adapted to handle extreme temperatures. An example is where wireless sensors monitor the transport of frozen foods, pharmaceuticals, tissue samples, and transplant organs at temperatures as low as -80°C.

Lithium thionyl chloride (LiSOCl2) batteries are constructed two ways: bobbin-type and spiral wound. Bobbin-type LiSOCl2 batteries are preferred for long-term deployments that draw low average daily current, including automatic meter reading/advanced metering infrastructure (AMR/AMI), M2M, SCADA, tank level monitoring, asset tracking, environmental sensors, and applications that involve extreme temperature cycles.

Bobbin-type LiSOCl2 batteries feature the highest capacity and highest energy density of any lithium cell, along with an extremely low annual self-discharge (less than 1% per year for certain cells), thus enabling up to 40-year battery life. Bobbin-type LiSOCl2 batteries also deliver the widest possible temperature range (-80 to 125°C) and feature a superior quality glass-to-metal hermetic seal.

The annual self-discharge rate of a bobbin-type LiSOCl2 battery can vary significantly based on the method of manufacturing and the quality of the raw materials. For example, a superior-quality bobbin-type LiSOCl2 cell can have an annual self-discharge rate as low as 0.7% and can retain over 70% of its original capacity after 40 years. By contrast, an inferior-quality bobbin-type LiSOCl2 cell can have a self-discharge rate of up to 3% per year, losing 30% of its available capacity every 10 years, making it impossible to realize a 40-year battery life.

The impact of a higher self-discharge rate may not become apparent for years. Consequently, applications that need a battery with a long operating life, especially in extreme environments, require some thorough due diligence: Designers should demand fully documented long-term test results, in-field performance data, as well as customer references from potential battery suppliers.

Specially modified bobbin-type LiSOCl2 batteries can be adapted to handle extreme temperatures. An example is where wireless sensors monitor the transport of frozen foods, pharmaceuticals, tissue samples, and transplant organs at temperatures as low as -80°C. Bobbin-type LiSOCl2 batteries can also handle extreme heat. For example, Awarepoint, a maker of real-time location systems, chose LiSOCl2 batteries for use in active RFID tags on medical equipment. The tags could go through autoclave sterilization, where temperatures can reach 135°C, without having their batteries removed.

Long-life bobbin-type LiSOCl2 batteries are almost exclusively utilized in meter transmitter units (MTUs) for AMR/AMI applications. The extended battery life of a bobbin-type LiSOCl2 cell is valuable to utility metering because a large-scale battery failure can disrupt customer billing systems and disable remote service start-up and shut-off capabilities. Fear of such chaos could force a utility company to invest millions of dollars to prematurely replace batteries so as not to jeopardize data integrity.

High pulses and two-way wireless

The rapid growth of the IIoT has boosted the use of remote wireless devices that require high pulses to support two-way wireless communications. A standard bobbin-type LiSOCl2 battery features a low rate design and thus cannot easily deliver the high pulses needed for two-way wireless communications. This obstacle can be overcome simply by combining a standard bobbin-type LiSOCl2 cell with a patented hybrid-layer capacitor (HLC). The standard LiSOCl2 cell delivers low daily background current when the device is in stand-by mode, while he HLC works like a rechargeable battery to deliver periodic high pulses.

Many consumer electronics products employ supercapacitors to deliver high pulses. Supercapacitors are not generally recommended for use in industrial applications because they have serious drawbacks, including short-duration power, linear discharge qualities that do not allow for use of all the available energy, low capacity, low energy density, and high annual self-discharge rates (up to 60% per year). When supercapacitors are linked in series, they require the use of cell-balancing circuits which add cost, increase size, and draw additional current.

High pulse requirements exhaust more energy, so long-term deployments invariably need to conserve as much energy as possible. There are three usual approaches to minimize power demand: by employing a low-power communications protocol (i.e. ZigBee, WirelessHART, LoRa, etc.); by intelligent circuit design and assembly, including the use of low-power microprocessors and components; and by maximizing the amount time spent in the stand-by state while minimizing energy consumption during data interrogation and transmission.

A growing number of IIoT applications are powered by energy harvesting devices in combination with Li-ion rechargeable batteries that store the harvested energy. While photovoltaic (PV) panels are a common form of energy harvesting, other methods can be used to extract small amounts of energy from equipment vibration, temperature variances, and ambient RF/EM signals. Energy harvesting is especially beneficial for applications that draw an average daily current that would prematurely exhaust a primary lithium battery. Common examples include solar-powered animal tracking devices that enable ranchers to continually track cattle herds, and solar-powered parking meters that both enable automated fee collection and identify open parking spots to help reduce pollution and traffic congestion.

Consumer-grade rechargeable Li-ion cells work well if the device is easily accessible, requires a maximum operating life of five years and 500 recharge cycles, and operates within a moderate temperature range (0-40°C), with no high pulse requirements. However, an industrial grade rechargeable Li-ion battery will likely be necessary if the application involves a long-term deployment in a remote location or extreme environment, or if high pulses are required.

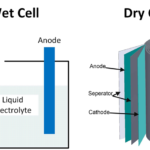

Industrial grade Li-ion batteries can operate for up to 20 years and deliver 5,000 full recharge cycles and feature an expanded temperature range of -40 to 85°C, including the ability to deliver high pulses (5 A for a AA-size cell). These ruggedly constructed cells also feature a hermetic seal that offers superior safety protection versus consumer-grade rechargeable Li-ion batteries.