A new Battery Test System (BTS) for electric vehicle (EV) testing is designed to help tier-one suppliers and automakers adapt to the complexity and scale of EV battery testing through enhanced customization, automation, and connection of data across the entire battery test workflow to ensure performance and accelerate time to market.

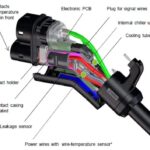

Batteries are at the core of the shift to electrification and have a direct impact on the sustainability, safety, performance and, consequently, consumer  buy-in of EVs. However, testing of EV batteries places immense strain on engineering resources as design and test groups must continuously upgrade and adapt to new test requirements.

buy-in of EVs. However, testing of EV batteries places immense strain on engineering resources as design and test groups must continuously upgrade and adapt to new test requirements.

NI’s Battery Test System enables scalability of testing by providing an out-of-the-box experience for battery test workflows, along with customization capability to fit a variety of test roles and needs. NI’s software-connected system is uniquely positioned to integrate components for battery test such as power electronics, environmental chambers, measurements, and test channels at scale. It facilitates coordination of activities between design and test teams to request, configure, run, monitor, and report on test results that inform critical design changes.

“Automakers are investing heavily to deliver on EVs timelines, which has placed increased importance on test to ensure this technology meets both time commitments and consumer expectations for safety,” said Drita Roggenbuck, Senior Vice President and General Manager of the Transportation Business at NI. “NI’s Battery Test System combines decades of test and measurement experience with our powerful software to enable automakers to test their batteries at scale, within budget and at pace with market demands.”

With its recent acquisition of NH Research Inc. (NHR), Heinzinger Automotive GmbH, and Kratzer Automation, NI’s global capabilities for EV battery test provide automakers with a cross-functional, scalable network of products, services, and solutions to meet current and future EV market demands. Additionally, NI’s SystemLink™, BTS software, and data analytics tools work together to ensure traceability of test results, repeatability of the tests themselves, and management of the entire test-cell and test lab operation, ultimately bringing modern software engineering tools and practices into battery testing.

National Instruments Corp., 11500 N Mopac Expwy, Austin, TX 78759-3504, ni.com/evtest.

Tell Us What You Think!