Today on Battery Power Tips

April 2024 Issue: Internet of Things Handbook

Engineering connections REMEMBER when the estimated number of connected devices in 2005 was around six billion, followed about five years later with the acronym “IoT” achieving buzzword/hype status? Now fast forward to next year, when that number is expected to skyrocket to a staggering 75 billion, or roughly nine devices per person on the planet.…Liquid cooled battery charger available in compact form

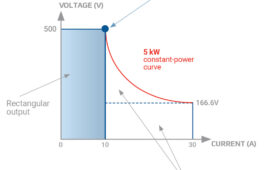

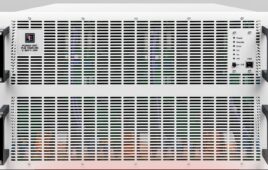

Bel Fuse Inc. is announcing the release of its BCN25-1000 Series — a 25 kW, liquid-cooled battery charger that converts 3-phase AC voltage to DC voltage.Online calculator assists in energy-harvesting designs

Nexperia announced the release of the Energy Balance Calculator. A powerful web-based tool designed to assist battery management engineers in maximizing the battery life of their applications. The calculator facilitates the integration of Nexperia’s Energy Harvesting PMICs into their systems by providing engineers with precise data for informed decision-making. At the core of Nexperia’s Energy Harvesting PMICs…How can quantum sensors and quantum batteries improve electric vehicle operation?

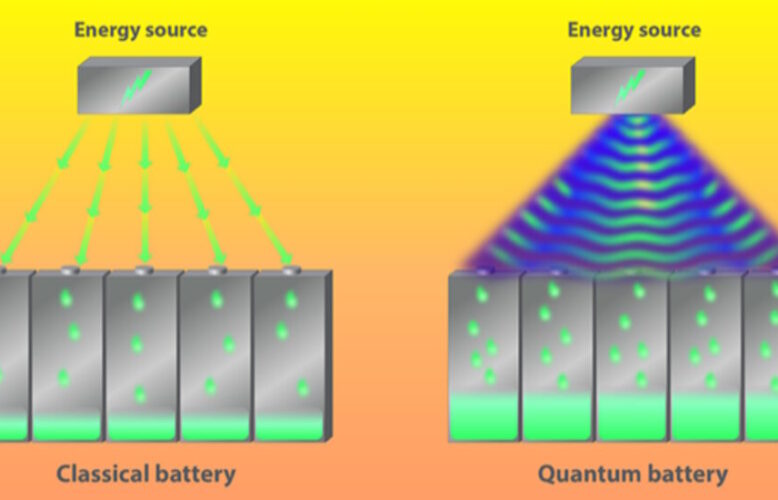

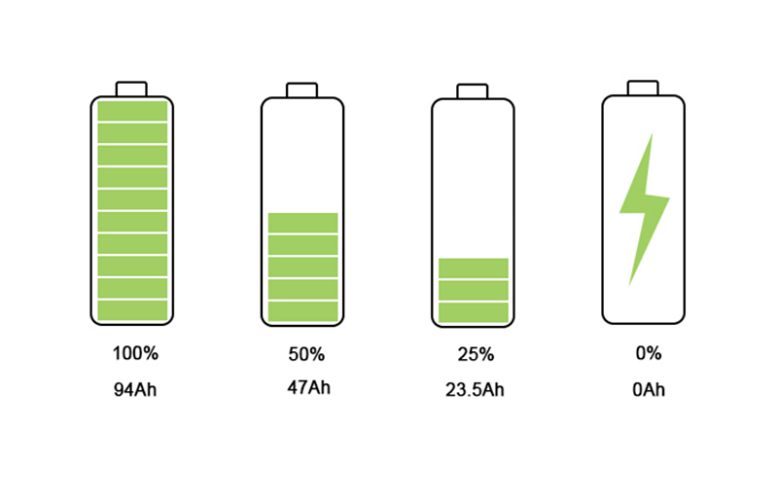

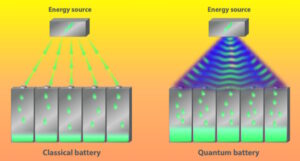

In the near term, quantum sensors are being developed that can more accurately measure EV battery capacity, assess battery safety, and reduce vehicle weight. In the longer term, quantum batteries have been proposed that could dramatically improve the speed and efficiency of battery charging. The energy remaining in an EV battery has been estimated using…February 2024 Issue: Power Electronics Handbook

Cold starts, hot power markets, and great expectations Recent cold spells across the United States have shifted the focus from “range anxiety” in electric vehicles (EVs) to concerns about their performance in cold…how they start, and how far they can go. Buzzworthy? Apparently. Newsworthy? Maybe, but it’s not new news. Reflecting on a youthful…Research shows improvements for fast-charging of Li-ion batteries

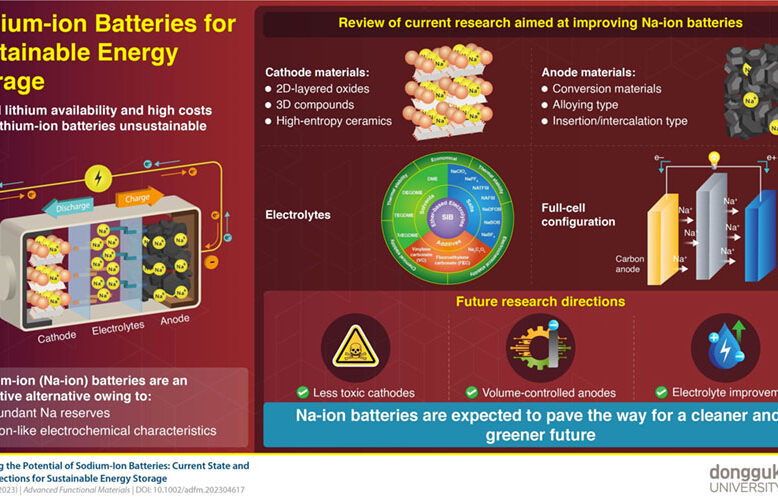

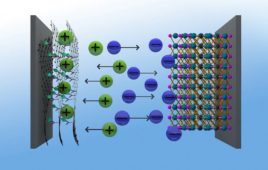

Researchers at Chung-Ang University used high-concentration electrolytes to improve safety and prevent cell swelling caused by lithium plating. To achieve a greater adaption of electric vehicles, the automotive industry needs fast-charging batteries that don’t compromise energy density. Lithium plating for ultra-fast charging raises safety concerns due to high cell polarization, requiring careful attention. During fast…Stationary Power See More >

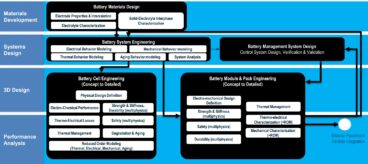

How does MBSE work for EV and stationary battery energy storage systems?

Model-based systems engineering (MBSE) is comprehensive. The International Council on Systems Engineering (INCOSE) defines MBSE as the “formalized application of modeling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.” It’s especially applicable to complex systems of systems like…

Robotics See More >

Battery management system targets robotics, AGV, 2/3-wheeler apps

The new i-BMS Battery Management System from Lithium Balance, acquired by Sensata earlier in the year, is a cell chemistry agnostic, compact, integrated BMS developed for the cost-optimized mass-production of applications up to 60 V, such as two and three-wheelers, automated guided vehicles (AGVs), and robotics. The i-BMS is a long-term solution for customers who […]

Automotive See More >

Research shows improvements for fast-charging of Li-ion batteries

Researchers at Chung-Ang University used high-concentration electrolytes to improve safety and prevent cell swelling caused by lithium plating. To achieve a greater adaption of electric vehicles, the automotive industry needs fast-charging batteries that don’t compromise energy density. Lithium plating for ultra-fast charging raises safety concerns due to high cell polarization, requiring careful attention. During fast…

Renewables See More >

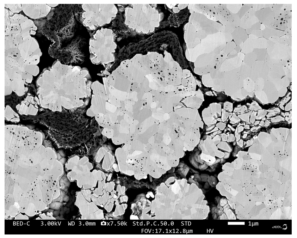

How scanning electron microscopy is helping researchers develop better lithium-ion batteries

By Pamela Mansfield, JEOL USA As the market for renewable energy sources and electric vehicles grows, the need for reliable, high-capacity energy storage is increasing too. Lithium-ion batteries (LIBs) fit the bill in many ways, but plenty of challenges remain ahead, such as understanding their microstructure. This article describes how scanning electron microscopy (SEM) can…

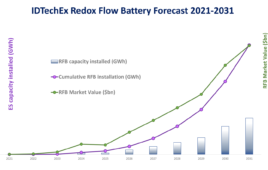

Li-ion batteries might lose their leadership in stationary applications, discusses IDTechEx

Crown Battery will buy RECs and eventually source local renewables to take operations 100% green

Power Edison to supply 12-MWh mobile battery system to U.S. utility