So far, this series of FAQs has looked at battery options for mobile robots, the most common powering option for robots, and the benefits of fuel cell power robot platforms were reviewed, including extended run times and faster recharge rates compared with battery power. Supercapacitors (also called ultracapacitors) bring another unique set of benefits to robot power systems, including ultra-fast recharging, higher power delivery rates, and extended temperature operation. In some systems, supercapacitors are paired with batteries, and the hybrid solution has its own unique attributes.

Differences in internal resistance between supercapacitors and batteries are a major source of the performance differences between the two types of energy storage devices. For example, when an application’s burst of energy is needed, the battery voltage decreases due to its high internal resistance and inability to support high surges. Supercapacitors have low internal resistances that enable them to deliver high bursts of energy with no damage to the device.

So, while batteries have significantly higher energy densities, supercapacitors can support higher power bursts. In some robot power applications, that makes them natural “partners.” In a hybrid system, supercapacitors can support any instantaneous energy demands, protecting the batteries, and the batteries can provide long-term stable energy flows. That can extend battery runtimes and prevent declining charge capacity as the battery ages.

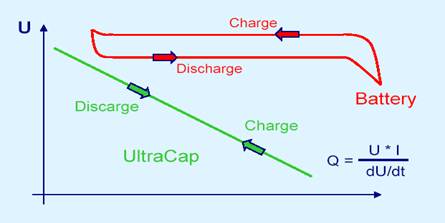

Supercapacitors (UltraCap) can be charged and discharged simultaneously, while batteries are limited by their slower charge rate. (Image: Tecate Group)

Supercapacitors are too heavy to use unmanned aerial vehicles or drones and are generally not cost-effective for large electric vehicles. However, in systems such as logistics robots and automated guided vehicles (AGVs), supercapacitors or hybrid supercapacitors and Li-ion battery power systems can be effective. The high cycle life of supercapacitors is a major benefit in logistics robots, AGVs, and similar applications that can benefit from round-the-clock operation seven days per week. Compared with supercapacitors, the cycle lives of batteries are orders of magnitude lower.

The battery is the primary energy source in an automotive application, and supercapacitors are used for regenerative braking or other auxiliary power demands. In logistics robots and similar systems, the roles can be reversed, and the supercapacitors become the primary power source, benefiting from frequent opportunities for quick recharging. At the same time, the batteries act as a supplemental power source when recharging opportunities are scarce.

Supercaps are cool in e-grocery fulfillment centers

Micro-fulfillment centers are springing up to service the needs of e-grocery and other emerging applications. Cold storage for frozen foods or fresh vegetables and meats is often found in these new micro-fulfillment centers. Lithium-ion (Li-ion) batteries do not provide optimal performance in low-temperature environments. As a result, some of the robots in these new distribution centers have swapped out Li-ion batteries for supercapacitors.

In general, supercapacitors can be used at lower temperatures compared with batteries. That makes supercapacitors useful in the chilled and frozen sections of e-grocery micro-fulfillment centers. Supercapacitors have cycle lives of 100,000 cycles and more, while Li-ions are limited to several thousand cycles, at best. The much longer cycle life and ability of supercapacitors to recharge in seconds make them useful in these applications. The robots are needed to operate continuously in three temperature zones.

The cell management systems (CMS) needed by hybrid supercapacitors are simpler than the battery management systems (BMS) required when using Li-ion batteries. A Li-ion BMS needs to be concerned with safe operation. A CMS for supercapacitors is concerned with cell voltage equalization to maximize cell operating life. Supercapacitor lifetime is related to the applied voltage and operating temperature. Higher temperatures and higher operating voltages at the cell level cause the ESR to increase faster and reduces supercapacitor lifetimes.

A wide range dc/dc converter rated from full rated voltage to one-half of rated voltage for optimal system performance is needed for supercapacitors. That’s different from batteries that operate as a constant voltage source. The use of an optimal dc/dc converter enables the use of all the stored energy, enabling the use of smaller supercapacitors, reducing solution size and cost.

Supercapacitor-powered logistics robots perform well in cold-storage environments. (Image: Alert Innovation)

Supercapacitors plus motor drives for robots

Supercapacitor modules are being used in industrial settings to ensure machines and robots curing grid power outages, level peak loading needs, and recover braking energy. Called UltraCap “DLC modules,” these energy storage modules have a nominal voltage of 95V and can be connected in series to provide the required voltage for a specific application. Depending on the application, they are connected to a dc/dc converter directly to the dc link in the motor drive being supported. The ambient operating conditions and the state of health of the supercapacitors can be monitored in real-time using the integrated communications bus.

Supercapacitor modules provide backup power for industrial machines, including stationary robots. (Image: Siemens)

The Smart Power Management (SPM) backup power system combines energy storage with power management. It is designed to ensure machines and robots continue to operate even with unreliable grids, that peak loads are avoided, and braking energy utilized. Before installing the SPM, the load profile of the operating environment is analyzed to identify opportunities to optimize power flow and availability. As needed, additional electrolytic capacitors, flywheel energy storage, or even rechargeable batteries can be added to the basic supercapacitor energy storage system. The use of the SPM improves robot productivity, reduces energy costs, and lowers CO2 emissions.

Asymmetric supercapacitors

Hybrid supercapacitors, also called Li-ion capacitors, are asymmetric devices with operating characteristics between Li-ion batteries and conventional (symmetric) supercapacitors. The operating voltage of hybrid supercapacitors is 3.8V compared with 2.5V for symmetric supercapacitors. Hybrid supercapacitors have much higher capacitance and energy densities (up to 10X) and lower self-discharge and standby current than symmetric supercapacitors.

But there are areas where symmetric supercapacitors outperform hybrid devices: symmetric supercapacitors have lower ESRs, and therefore higher power capabilities; symmetric devices have wider operating temperature ranges; and symmetric devices can be discharged to zero volts, while hybrid devices can only be discharged to a minimum of about 2.2V. Due to that last difference, a different CMS is needed when using hybrid supercapacitors compared with symmetric devices.

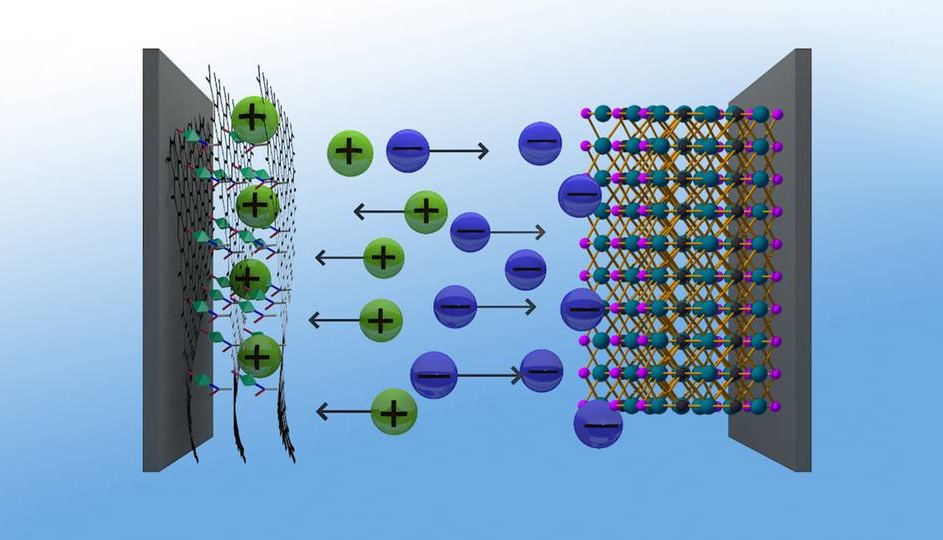

Researchers have proposed the use of a sustainable graphene hybrid material as the positive electrode in supercapacitors. It is combined with a proven negative electrode based on titanium and carbon. The resulting “asymmetrical” energy storage device can provide an energy density of 73 Wh/kg, similar to that of a nickel-metal-hydride (NiMH) rechargeable battery, and much better the 16 kW/kg power density delivered by conventional supercapacitors.

The new hybrid positive electrode is based on chemically modified graphene combined with a nanostructured metal organic framework (MOF). The hybrid material has a large specific surface area, up to 900 square meters per gram, controllable pore sizes, and high electrical conductivity.

Graphene hybrids (left) made from metal organic frameworks (MOF) and graphenic acid make an excellent positive electrode for supercapacitors, which achieve an energy density similar to nickel-metal hydride batteries. (Image: Technical University of Munich)

Strong chemical bonds between the components are required to produce a chemically stable hybrid structure. In this instance, there is a stable and strong connection between the graphenic acid and the MOF. As a result of the stability of the bonds, more charge/discharge cycles are possible without performance degradation. While a conventional Li-ion battery can have a useful life up to about 5,000 cycles, the new hybrid supercapacitor cell retains nearly 90% of its capacity after 10,000 cycles.

Summary

Compared with batteries discussed in the first FAQ in this series and fuel cells that were the focus of the second FAQ, supercapacitors can bring unique performance benefits to specific classes of robots and robot use cases. Li-ion batteries have significantly higher energy densities than supercapacitors, but supercapacitors have much higher power densities and longer cycle lifetimes. As a result, hybrid systems incorporating both batteries and supercapacitors can provide benefits beyond those possible with a single-technology solution. In addition, supercapacitors themselves are evolving and becoming “hybrid” devices that incorporate capabilities of conventional supercapacitors and rechargeable batteries in a single device. Today’s Li-ion capacitors are asymmetric devices with operating characteristics between Li-ion batteries and conventional (symmetric) supercapacitors. Developing more advanced forms of asymmetric (hybrid) supercapacitors is ongoing and will expand applications for supercapacitors. The fourth and concluding FAQ in this series will consider operating robots using energy harvesting and ambient energy sources.

References:

Supercapacitors challenge batteries, Technical University of Munich

Supercapacitors in Tandem with Batteries to Prolong the Range of UGV Systems, MDPI

Supercapacitors vs. Batteries, Kemet

UltraCap modules for efficient energy storage in machines, Siemens

A short note to add to use cases:

We have also seen our ultrathin hybrid PowerRESPONDER (TM) supercapacitor being used as a backup power source that is built into the electronics at board level while the battery pack is swappable in the product. ENsuring capture of critical data in event of a power failure.