by Luca Vezzadini, ZIVAN The urgency of mitigating climate change and reducing greenhouse gas emissions has prompted businesses to adopt more sustainable transportation solutions, particularly electric vehicles (EVs). Lithium-ion batteries (LIBs) are at the forefront of electrification. McKinsey predicted that the entire LIB chain, from mining through recycling, could grow by over 30% annually from 2022…

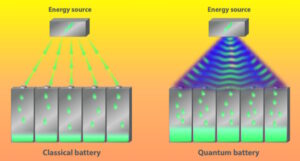

How can quantum sensors and quantum batteries improve electric vehicle operation?

In the near term, quantum sensors are being developed that can more accurately measure EV battery capacity, assess battery safety, and reduce vehicle weight. In the longer term, quantum batteries have been proposed that could dramatically improve the speed and efficiency of battery charging. The energy remaining in an EV battery has been estimated using…

24mm lithium coin cell holder space-saving and top-loading

A breakthrough lithium coin cell holder for maximizing PC board capacity when installing high-capacity 2477 lithium coin cells in high-density applications is now available from Keystone Electronics. Its top-loading design allows for minimal footprint board layouts without restricting battery access in devices. This sturdy holder is supplied in a thru-hole version and is extremely rugged,…

$131 Million to boost America’s battery supply chain and supercharge electric vehicle innovation

The US Department of Energy (DOE) today announced more than $131 million for projects to advance research and development (R&D) in electric vehicle (EV) batteries and charging systems and funding for a consortium to address critical priorities for the next phase of widescale EV commercialization. The advanced battery consortium will work towards developing advanced technologies…

Trigger alerts when Li-ion batteries get too hot

TTape from Littelfuse, set of temperature-triggered switches, raises a bit that indicate hot batteries. Li-ion batteries can get hot, which can cause failures or worse in the products they power. Thus, it’s important to monitor their temperature and act before damage occurs. You can monitor temperature with a set of thermocouples, scan them, and write…

What are e-bikes?

In this article, we’ll explore the types of e-bikes available and their features. In terms of e-mobility, e-bikes stand out as a compact, affordable option for many.

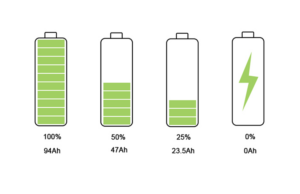

What is an EV battery state of charge (SOC)?

An electric vehicle (EV) battery state of charge (SOC) represents energy levels as a percentage. Analogous to an internal combustion engine (ICE) fuel gauge, SOC clearly indicates available energy that directly corresponds to the driving range. This article explains how SOC is calculated and explores the different methods used to determine these calculations. It also…

Battery pack keeps its cool

XING Mobility has announced the official release of its IMMERSIO Cell-to-Pack (CTP) product at the IAA Mobility show in Munich, Germany. This innovative battery pack, which features high energy density and exceptional heat dissipation and safety features, will be presented for the first time to the global audience at the event. XING’s IMMERSIO CTP Solution…

Battery testing: critical to the rise of electric vehicles

When designing a battery into an EV, you must perform rigorous testing to understand a battery’s performance. Electric vehicles (EVs) accounted for 13% of global vehicle sales in 2022 and are forecasted to reach 30% of global vehicle sales by 2030. The industry needs to continue working on making EVs affordable to support this transition…

SMT isolation transfers measure just 7.2 x. 485 mm

XING Mobility has announced the official release of its IMMERSIOTM Cell-to-Pack (CTP) product at the IAA Mobility show in Munich, Germany. This innovative battery pack, which features high energy density and exceptional heat dissipation and safety features, will be presented for the first time to the global audience at the event. XING’s IMMERSIO CTP Solution…