Battery electric vehicles (BEV) and fuel cell electric vehicles (FCEV) are two “zero-emissions” vehicles. Although none achieve zero emissions, as discussed below. The amount of energy stored in a battery or hydrogen tank for a FCEV can be measured in two ways:

- Energy Density: Energy per unit volume, also known as volumetric energy density

- Specific energy: Energy per unit mass, also known as gravimetric energy density. When referring to a fuel itself, specific energy is typically used. The term gravimetric energy density is typically used to refer to the combined energy per unit mass of a fuel tank and the fuel it contains.

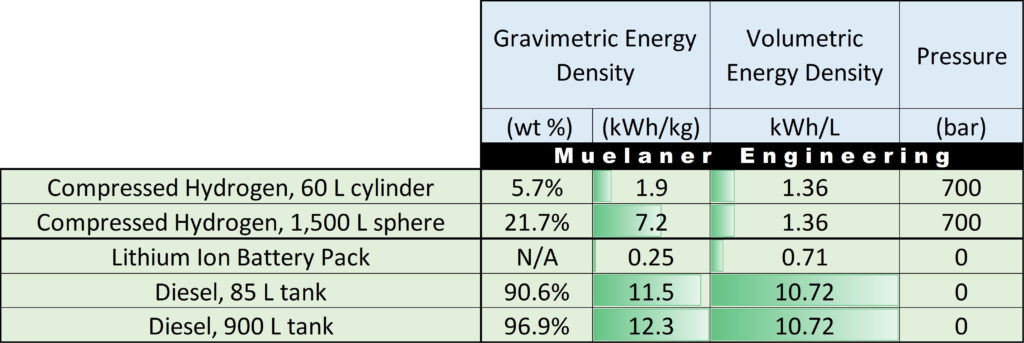

Batteries are a highly energy-efficient way to store electricity. Unfortunately, compared to liquid petroleum-based fuels, batteries store far less energy – both by volume and mass. Although the gravimetric energy density of a lithium-ion battery pack can be as much as 50 times less than a diesel tank, an internal combustion engine and gearbox are much heavier than an electric motor. The combined mass of the powertrain for a BEV is only about 30 percent heavier than a fossil-fuelled vehicle.

Batteries are a highly energy-efficient way to store electricity. Unfortunately, compared to liquid petroleum-based fuels, batteries store far less energy – both by volume and mass. Although the gravimetric energy density of a lithium-ion battery pack can be as much as 50 times less than a diesel tank, an internal combustion engine and gearbox are much heavier than an electric motor. The combined mass of the powertrain for a BEV is only about 30 percent heavier than a fossil-fuelled vehicle.

When it comes to hydrogen, the picture is even more confusing. Hydrogen itself is very light, giving it specific energy greater than liquid fuels. However, uncompressed hydrogen is extremely bulky and couldn’t fit into any practical vehicle. Compressing or liquifying hydrogen requires very high-pressure tanks, weighing far more than the hydrogen they contain. For example, the Toyota Mirai stores 5 kg of hydrogen compressed to 700 bar in composite tanks weighing 83 kg – a gravimetric density of 5.3%. The gravimetric energy density of a hydrogen tank in a car or truck is much lower than a tank containing liquid petroleum fuel.

The gravimetric energy density of a fuel tank depends on the tank’s size; bigger tanks have a higher energy density. This is because the volume increases by the cube of its dimensions, while the material used to construct the tanks depends on its surface area, which increased by the square of its dimensions. Imagine a cube, one meter in each dimension, with walls made from a material weighing 1 kg/m2. This would store one cubic meter of fuel and have an external surface area of six square meters, giving a weight of 6 kg/m3. If the dimensions are increased to two meters, the volume becomes eight cubic meters, and the surface area is 24 m2 giving a weight of 3 kg/m3. This is a linear relationship, assuming constant wall thickness, increasing the dimensions of a tank by x will divide its mass per unit volume by x. This means that the larger the vehicle, the more practical hydrogen becomes.

For passenger cars, hydrogen offers very little energy storage advantage over a battery once the additional mass of the fuel cell and the auxiliary battery is accounted for. This is demonstrated by the fact that state-of-the-art BEVs and FCEVs have a comparable range and electrical energy consumption at the motor. The actual energy efficiency of the FCEV is far lower than the BEV because of much more significant energy losses when producing hydrogen, transporting it, and then using it to generate electricity in the fuel cell.

What does zero emissions mean?

There are three ways that a vehicle can be considered to be zero emissions:

- Tailpipe emissions: These are emissions directly coming from the vehicle while using. Both BEV and FCEV are generally considered to be entirely zero emissions by this definition. However, even this is not entirely true. Particulate emissions, a significant cause of respiratory disease, are primarily caused by the erosion of brakes and tires during use.

- Operational emissions: These emissions include tailpipe emissions and any emissions caused by supplying energy to the vehicle. For a fossil-fuelled vehicle, this includes emissions from fuel burned in the engine and by tankers supplying the fuel to the filling station and refining the fuel. An electric vehicle has emissions created by power generation and electrical supply. If the electricity is generated using coal, the operational emissions may be higher than fossil-fuelled vehicles. Almost all hydrogen is produced from natural gas or coal, with the CO2 released directly into the atmosphere. Vehicles fuelled in this way have very high operational emissions.

- Lifecycle emissions: These emissions include operational and emissions caused by manufacturing the vehicle and producing the vehicle’s materials. Batteries, fuel cells, and high-pressure tanks all require a lot of energy to produce. This means that zero-emissions vehicles often produce more emissions during manufacture than fossil-fuelled ones, meaning they have a carbon payback period.

What did you use as the sources for the energy density values in this article?

Hi Väinö,

Here are a few of my sources:

I attended the IMechE EV Batteries conference and took some figures from presentations. I read these papers:

Cao, W., J. Zhang, and H. Li, Batteries with high theoretical energy densities. Energy Storage Materials, 2020. 26: p. 46-55.

Zhu, K., et al., How Far Away Are Lithium-Sulfur Batteries From Commercialization? Frontiers in Energy Research, 2019. 7(123).

Some more in-depth references are given in the SAE EDGE report on power options for commercial vehicles that I wrote recently:

https://www.sae.org/publications/technical-papers/content/epr2021021/