How to wind wire that’s square

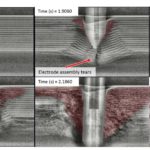

Is it hip to be square? Apparently it is when you’re talking about motor and actuator windings  where the use of square wire leads to squeezing more copper into every cross-sectional unit of area, thereby boosting magnetic flux density. This device is an acceleration assist device made for Honda by Odawara Automation Inc. in Tipp City, Ohio. One of the tricky parts of winding square wire, explained Odawara president Chris Spejna, is that the winding machine must prevent the square wire from twisting, so the winding process takes a bit longer than that for ordinary wire. Odawara also constructs motor stators with square wire fashioned into hairpin shapes. For those parts, the hairpin-shaped pieces get automatically soldered once they are in place on the stator form.

where the use of square wire leads to squeezing more copper into every cross-sectional unit of area, thereby boosting magnetic flux density. This device is an acceleration assist device made for Honda by Odawara Automation Inc. in Tipp City, Ohio. One of the tricky parts of winding square wire, explained Odawara president Chris Spejna, is that the winding machine must prevent the square wire from twisting, so the winding process takes a bit longer than that for ordinary wire. Odawara also constructs motor stators with square wire fashioned into hairpin shapes. For those parts, the hairpin-shaped pieces get automatically soldered once they are in place on the stator form.

NEXT PAGE: Here come “structural” batteries