by Luca Vezzadini, ZIVAN The urgency of mitigating climate change and reducing greenhouse gas emissions has prompted businesses to adopt more sustainable transportation solutions, particularly electric vehicles (EVs). Lithium-ion batteries (LIBs) are at the forefront of electrification. McKinsey predicted that the entire LIB chain, from mining through recycling, could grow by over 30% annually from 2022…

Liquid cooled battery charger available in compact form

Bel Fuse Inc. is announcing the release of its BCN25-1000 Series — a 25 kW, liquid-cooled battery charger that converts 3-phase AC voltage to DC voltage.

Research shows improvements for fast-charging of Li-ion batteries

Researchers at Chung-Ang University used high-concentration electrolytes to improve safety and prevent cell swelling caused by lithium plating. To achieve a greater adaption of electric vehicles, the automotive industry needs fast-charging batteries that don’t compromise energy density. Lithium plating for ultra-fast charging raises safety concerns due to high cell polarization, requiring careful attention. During fast…

Battery pack keeps its cool

XING Mobility has announced the official release of its IMMERSIO Cell-to-Pack (CTP) product at the IAA Mobility show in Munich, Germany. This innovative battery pack, which features high energy density and exceptional heat dissipation and safety features, will be presented for the first time to the global audience at the event. XING’s IMMERSIO CTP Solution…

Battery testing: critical to the rise of electric vehicles

When designing a battery into an EV, you must perform rigorous testing to understand a battery’s performance. Electric vehicles (EVs) accounted for 13% of global vehicle sales in 2022 and are forecasted to reach 30% of global vehicle sales by 2030. The industry needs to continue working on making EVs affordable to support this transition…

EV battery tests involve lots of power

In a video, EE World spoke with a power-supply applications engineer about why RV batteries use such high voltages and how to test them. Batteries are perhaps the most expensive component of an electric vehicle. Typically producing 800 V to 900 V, batteries deliver the power needed move the vehicle. Of course, EV batteries need…

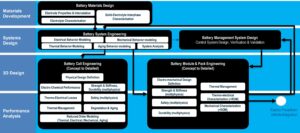

How does MBSE work for EV and stationary battery energy storage systems?

Model-based systems engineering (MBSE) is comprehensive. The International Council on Systems Engineering (INCOSE) defines MBSE as the “formalized application of modeling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.” It’s especially applicable to complex systems of systems like…

MOSFETs for battery protection circuits target mobile devices

Magnachip Semiconductor Corporation announced that the Company has released four new MXT LV Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs)*, using Super-Short Channel technology, to further expand Magnachip’s seventh-generation MXT LV MOSFET line-up for battery protection circuits of mobile devices. Super-Short Channel is Magnachip’s latest design technology to reduce Ron (the resistance of MOSFETs during on-state operation) by shortening the…

How is functional safety defined & implemented for batteries in EVs and BESS?

Li-ion batteries can store large amounts of energy, and they can support high rates of power delivery. They are the preferred energy storage technology for EVs and large battery energy storage systems (BESS). But if not properly managed, they can also present safety hazards. That makes functional safety a critical consideration when designing large Li-ion…

How does vehicle-to-grid technology work to improve sustainability?

Vehicle-to-grid (V2G) technology is often touted as one key to a more sustainable energy infrastructure. Like other areas where technology strongly impinges on economic and social interactions, however, the reality is complex and nuanced. Battery chargers can be a particularly daunting technical problem when implementing V2G. The charger must be bidirectional and offer high efficiency.…