A lot has been written regarding rechargeable lithium (LI) batteries and sustainability. Primary (non-rechargeable) Li batteries can also make major contributions to improving the sustainability of the systems where they are used. This FAQ reviews some of the factors related to the sustainability of primary Li batteries including key performance indicators (KPIs), downcycling versus recycling, the chemical content of batteries, battery lifespan, the development of digital twins and battery passports, and closes with a review of the latest editions of primary battery standards from the International Electrotechnical Commission (IEC).

Aren’t primary Li batteries being replaced by rechargeables?

It’s sometimes assumed that primary batteries are being increasingly replaced by more sustainable rechargeable batteries. That assumption is inaccurate on both counts. While the market for rechargeable batteries is growing faster, they are generally used in different applications than primary batteries, so the reality is a bit complicated.

The market for primary batteries is growing slower and their market share, compared with rechargeables, is shrinking. But that’s not the same as saying that the use of primaries is declining. In fact, the number of primary batteries is growing. For example, internet of things (IoT) applications like smart water meters, certain industrial and military/aerospace sensor applications, and medical devices all rely on primary batteries. But even that’s not so simple. In many instances, applications that previously used C-cells or D-cells now use smaller formats, especially coin cells. Based on the KPIs required by specific applications, primary batteries can provide a more sustainable option.

KPIs can be complicated

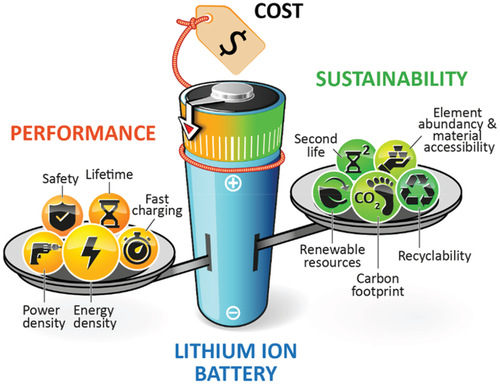

KPIs are highly application dependent. For example, portable applications can benefit from the highest possible energy density and a compact form factor while large-scale battery energy storage systems may need low installation costs and low operational costs. Plus, various applications have different regulatory requirements. Common technical performance KPIs include specific energy (Wh/kg), energy density (Wh/L), specific power (W/kg), and power density (W/L). in the past, batteries were developed to optimize specific performance KPIs with the lowest cost, and sustainability was a secondary consideration (Figure 1). That’s changing; KPIs related to sustainability like the life cycle carbon footprint, its use of sustainable materials and recyclability are growing in importance. Like the other factors considered, recyclability is complicated and includes the concept of downcycling.

Figure 1. Efforts to increase battery sustainability are balanced by needs for improved battery performance and cost considerations (Image: Wiley small methods).

Downcycling vs recycling

Downcycling refers to the imperfect recycling of materials. In downcycling, the recovered materials are less pure and/or less perfect compared with new materials and therefore can be less suitable for use in subsequent manufacturing operations. For example, when recycling certain plastics, it’s recommended that no more than 70% recycled material be used to ensure suitable performance from the recycled mixture. There’s a cost-benefit tradeoff between obtaining higher quality materials from downcycling versus higher processing costs.

To determine the optimal cost-benefit point, it’s necessary to quantify the quality reduction of recycled materials compared to new materials. A methodology using concepts related to thermodynamic, functional, and economic factors has been suggested for analyzing the effectiveness of downcycling.

- Thermodynamic downcycling refers to the thermodynamic effort required to reprocess the material. It includes energy, heat, and auxiliary material requirements. For example, thermodynamic downcycling analysis of metals uses direct remelting of the pure material as the baseline and compares any increase in energy needs for thermodynamic processing of the recycled material. Similar comparisons can be applied to other materials like plastics.

- Functional downcycling refers to recycled materials that are suitable for fewer applications compared to new materials. It can also refer to materials that are not suited for exclusive use in recycled products but require mixing with new materials. That occurs for many plastics where there’s a maximum amount of recycled material that can be used to ensure the quality of the product. Minimizing the impact of functional downcycling requires that the recycled materials are suitable for as many applications as possible.

- Economic downcycling refers to the reduced value of recycled material compared to new material. Using higher-cost recycling processes can sometimes result in less economic downcycling, but the increased costs need to be weighed against the added value that is captured.

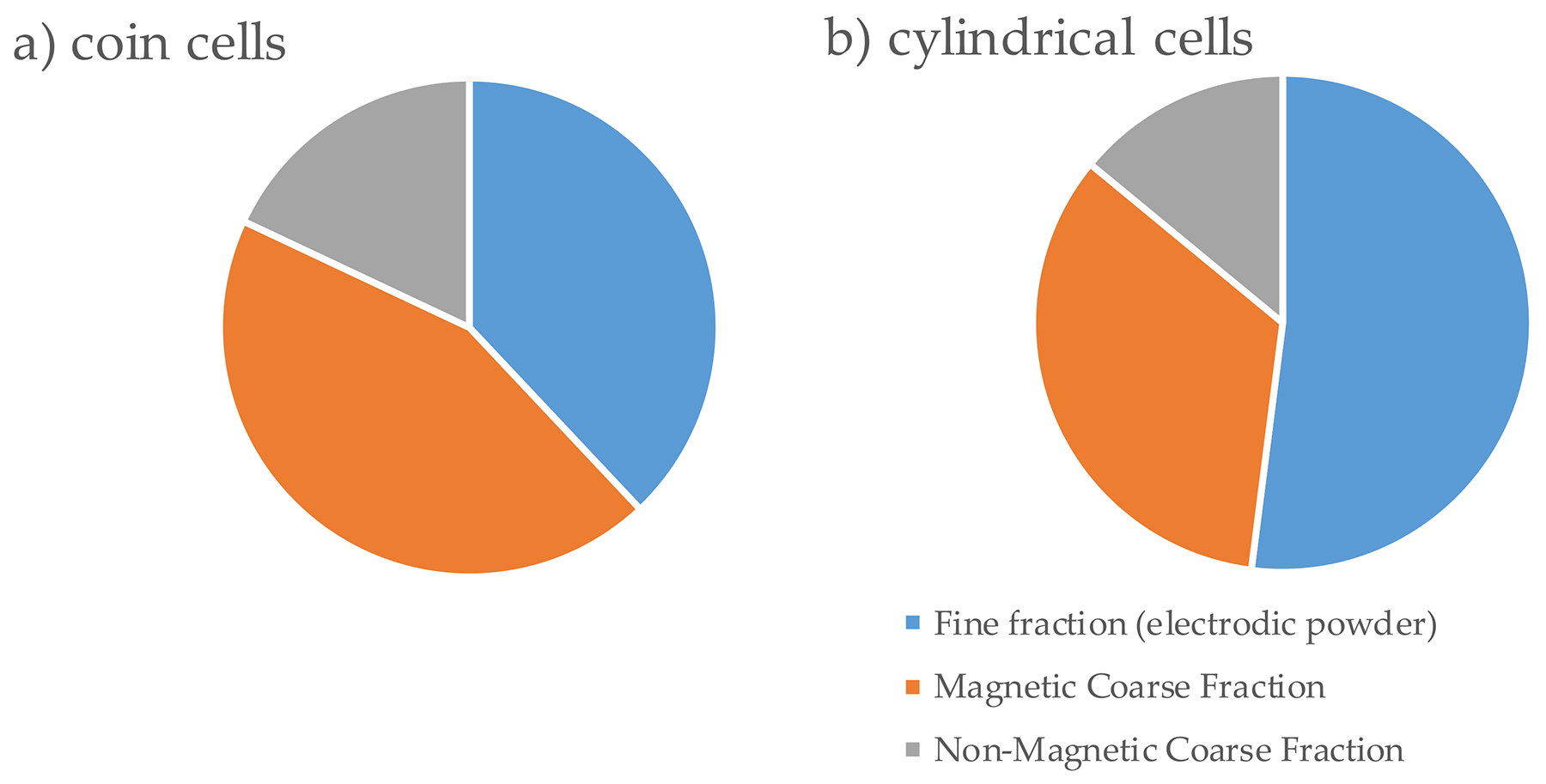

Not all products made using the same technology have equal downcycling potential. Consider LiMnO2 batteries as an example: 53% are cylindrical cells, 42% are coin styles, and 5% are other formats. An experiment was performed at a pilot scale that recycled coins and cylindrical cells. The varying percentages of materials in the two formats are a key factor determining the results of recycling. The experiment demonstrated that electrodic powder was the primary waste recovered from cylindrical cells while magnetic coarse material (the case) was the primary material recovered from the coin cells (Figure 2). The magnetic coarse material has an inherently lower value compared with the electrodic powder, making it more feasible to downcycle the cylindrical cells.

Figure 2. Waste materials content for coin (left) and cylindrical (right) LiMnO2 cells (Image: MDPI energies).

Digital twins and battery passports

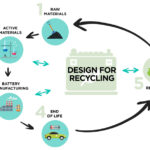

The Global Battery Alliance (GBA) is developing the Battery Passport framework to use digital twins to increase transparency throughout the battery value chain. The concept of a digital twin is particularly useful when considering battery sustainability. A digital twin is a comprehensive virtual digital model of a physical object like a battery. It can be used for design, simulation, testing, integration, maintenance, and other activities throughout the lifecycle of the object. It is used for comprehensive product lifecycle management including the final disposal of the object at end of life.

As envisioned by the GBA, a digital twin will be established for a physical battery that contains all the information relevant to the product lifecycle and sustainability. Its goal is to establish higher levels of transparency and sustainability for the entire battery lifecycle based on a circular battery value chain that supports standardized, comparable, and auditable data formats. The GBA expects to also develop a quality seal for battery sustainability to enable battery users to make informed choices when specifying batteries. While initially targeting rechargeable batteries for electric vehicles, the concepts contained in the Battery Passport can also be applied to primary batteries.

The proposed Battery Passport covers the entire value chain from mining battery materials to battery disposal at end of life. It includes technical parameters like material content and recyclability, the carbon footprint of battery production and use, and integrates the United Nations’ Child Labor and Human Rights Indices. The goals of the Battery Passport program are to create:

- A global framework of rules for measurement, reporting, and auditing of environmental, social, and governance (ESG) parameters for the entire battery value chain and product lifecycle.

- Unique digital identification for batteries including comprehensive ESG data, manufacturing history, and end-of-life parameters like recycling

- The ability to harmonize data and collaborate across the value chain and feed data into the battery passport framework.

- A digital platform for collecting, exchanging, correlating, and reporting data to enable transparent progress analysis to provide policymakers and governments with the information and tools needed to support increased battery sustainability.

- A quality mark for batteries to support battery users’ expectations for more sustainable solutions.

IEC primary battery standards

The IEC has an ongoing effort to develop standards for the performance, safety, and environmental aspects of primary batteries. Primary batteries are available that use a variety of chemistry and are manufactured in a wide range of sizes and formats (Figure 3). The applications of primary batteries are wide, ranging from toys to implanted medical devices. Because they are widely used, the IEC has recently published three new editions of the most referred to standards for primary batteries.

Figure 3. Primary batteries are available in a wide range of sizes and formats; the IEC has ongoing efforts to develop standards for them (Image: International Electrotechnical Committee).

IEC technical committee 35 (TC 35) is responsible for standards related to primary cells and batteries. The activities of TC 35 are wide-ranging and include performance, specifications, dimensions, and guidance related to environmental and safety issues. TC 35 has had a significant impact on primary battery recycling efforts. The three recently updated standards include:

- IEC 60086-1 sets basic requirements for and information on primary cells and batteries. Among the changes in the latest edition is a table for performance tests relating to storage and discharge conditions.

- IEC 60086-2 details more specific requirements and complements the basic and general information and requirements of IEC 60086-1.

- IEC 60086-3 specifies performance and safety requirements for primary batteries in watches and wearables.

Summary

Primary batteries have as much to contribute to increasing sustainability as rechargeable batteries. Developments in downcycling versus recycling can help improve battery sustainability. Additionally, the development of digital twins, so-called battery passports, and new editions of IEC standards for primary batteries can all contribute to improved sustainability for primary batteries.

References

A terminology for downcycling, Journal of Industrial Ecology

Are primary batteries a sustainable option?, International Electrotechnical Committee

Environmental Considerations for Lithium Batteries, Intertek

GBA Battery Passport, Global Battery Alliance

Lithium-based Battery Assessment, Resource Recycling Systems

Process Simulation for Li-MnO2 Primary Battery Recycling: Cryo-Mechanical and Hydrometallurgical Treatments at Pilot Scale, MDPI energies

Toward Green Battery Cells: Perspective on Materials and Technologies, Wiley small methods

Tell Us What You Think!