Lithium-ion batteries (LIBs) are complex electrochemical and mechanical systems subject to dozens of international safety standards. In this FAQ, we’ll discuss the key environmental aspects of LIB safety, review the top five LIB safety standards, and consider using custom-battery testing rooms for the safety of testing personnel.

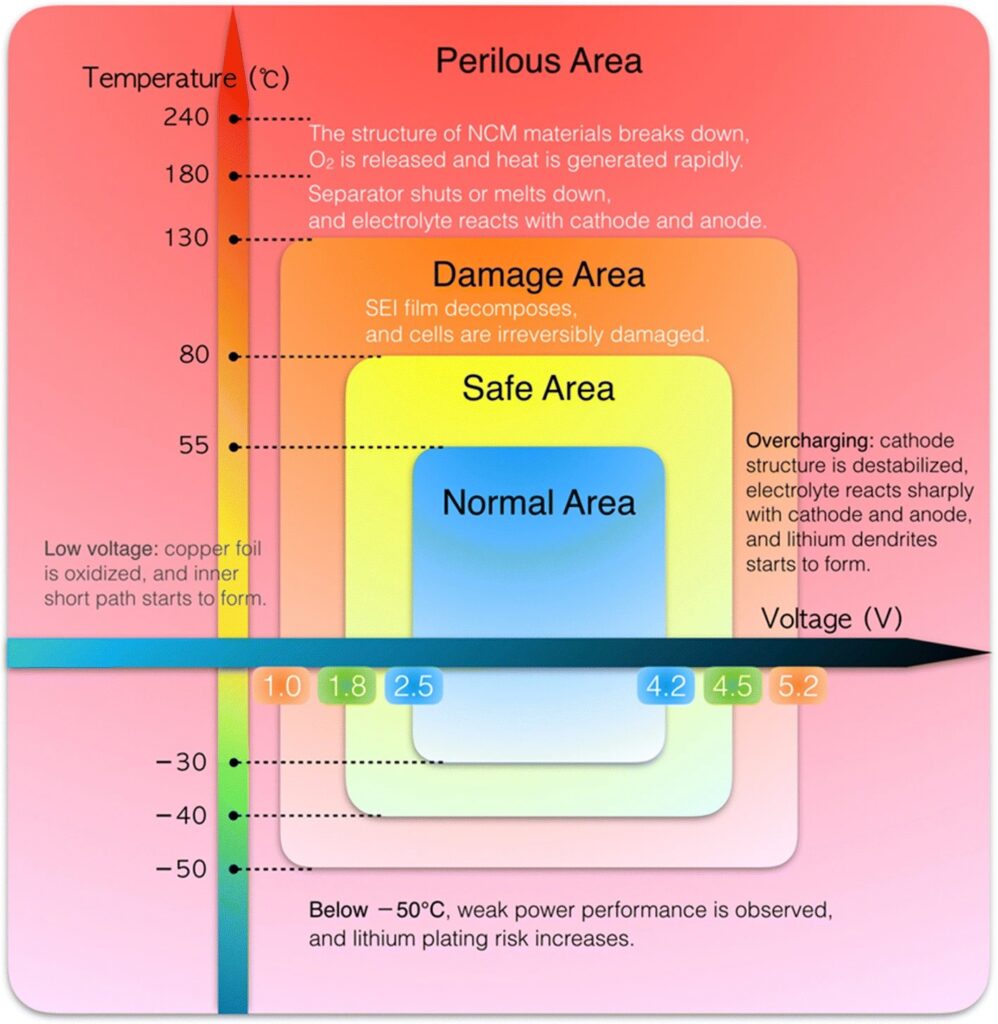

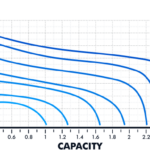

Many of the LIBs’ safety concerns are because the devices are voltage and temperature-sensitive. Figure 1 showcases the behavior of Li(Ni0.5Co0.2Mn0.3)O2 (NCM) cells. In this example, the cells are specified for operation from −30 to 55° C. At temperatures above 55° C (to about 80° C), the cells exhibit better rate-capability resulting from faster electrochemical reactions and fast ion migration in the electrolyte and electrodes. The side reactions, in this case, become severe, resulting in a fast-capacity decay.

In temperatures above 80° C, the cell begins to experience damage, and anything above 130° C will result in the constituent parts of the cell melting and potentially starting a fire.

Figure 1: Operating voltage and temperature are two factors that impact Li safety. This example is for NCM cells. (Image: Electrochemical Energy Reviews)

Low temperatures lead to poor cell performance and possible damage but are typically not a safety hazard. However, over-charging (too high a voltage) can result in the cathode decomposing and the electrolyte oxidizing, which is a safety concern. An over-discharge (too low of a voltage) can result in the decomposition of the solid electrolyte interface (SEI) on the anode and can cause copper foil oxidization, further damaging the cell.

In addition to operating and environmental concerns related to voltages and temperatures, mechanical damage can result in safety problems with LIBs. Given these concerns, there’s an equally wide range of safety standards for LIBs.

Five of the most common are:

- IEC 62133

- UN/DOT 38.3

- IEC 62619

- UL 1642

- UL 2580

The IEC 62133, Safety Test Standard of Li-Ion Cell and Battery, is the safety requirement for testing secondary cells and batteries containing alkaline or non-acid electrolytes. It’s used to test LIBs used in portable electronics and other applications. IEC 62133 addresses chemical and electrical hazards and mechanical concerns such as vibration and shock that can threaten consumers and the environment.

UN/DOT 38.3 (the T1-T8 Tests and UN ST/SG/AC.10/11/Rev. 5) covers transportation safety testing for all LIBs, lithium metal cells, and batteries. The test criteria include eight tests (T1 – T8) focusing on specific transportation hazards. UN/DOT 38.3 is a self-certifying standard and does not require independent third-party testing, but using third-party test labs is common to reduce the risk of litigation should an accident occur.

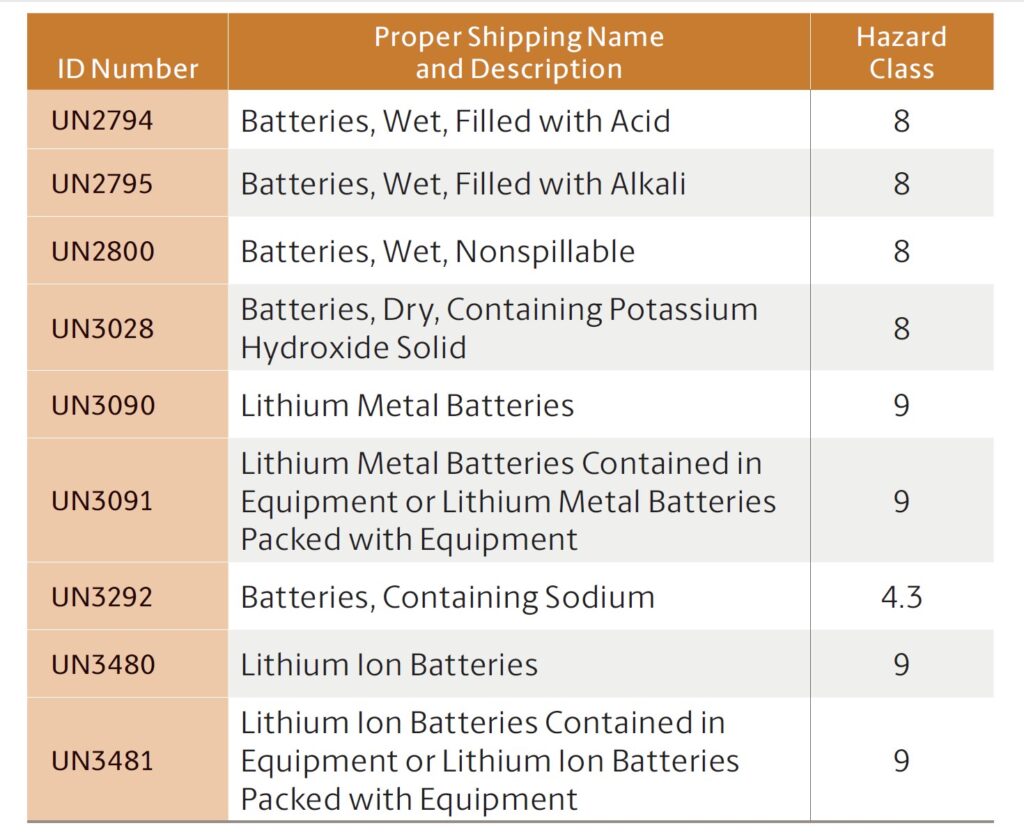

Several sub-classes of lithium batteries are recognized (Table 1), such as:

- UN 3090, Lithium metal batteries, shipped as components

- UN 3480, LIBs, shipped as components

- UN 3091, Lithium metal batteries shipped in equipment or packed with equipment

- UN 3481, LIBs shipped in equipment or packed with equipment.

Table 1: Many types of lithium batteries are considered hazardous materials and require special handling when shipped. (Image: UPS)

IEC 62619, which covers the safety standards for secondary lithium cells and batteries, specifies the requirements for the safe application of LIBs in electronics and other industrial applications. IEC 62619 standard test requirements apply to stationary and motive applications.

The stationary applications include telecom, uninterruptible power supplies (UPS), electrical energy storage system, utility switching, emergency power, and similar applications. The motive applications include forklift trucks, golf carts, auto-guided vehicles (AGVs), railway, and marine — excluding road vehicles.

UL 1642, the UL standard for safety for lithium batteries, provides standard requirements for primary and secondary lithium battery cells used as a power source in electronic products.

UL 1642 covers:

- Technician-replaceable Li batteries containing 5.0 g (0.18 oz) or less of metallic Li. Batteries with over 5.0 g of Li are judged on their compliance with the requirements, as applicable, with additional testing and examination to determine whether the battery is acceptable for its intended use.

- User-replaceable Li batteries containing 4.0 g (0.13 oz) or less of metallic Li and not more than 1.0 g (0.04 oz) of metallic Li in each electrochemical cell. Batteries with over 4.0 g or a cell with over 1.0 g of Li require further examination and testing to determine whether the cells or batteries are acceptable for their intended use.

UL 1642 does not cover the toxicity risk from ingesting a Li battery or the risk of bodily harm resulting from a battery that’s damaged or cut open, providing access to the metallic Li.

UL 2580x, the UL standard for safety for batteries for use in electric vehicles, is comprised of several tests, including:

Large current battery short circuit: run on fully charged samples. The sample will be short-circuited using a total circuit resistance ≤ 20 mΩ. A spark ignition detects the presence of flammable concentrations of gases inside the sample, and there can be no signs of explosion or fire. In addition, vapors will not vent outside except through designated ventilation openings or systems. There will not be a rupture of the enclosure or observable signs of electrolyte leakage. If the LIB remains operational after the short-circuit test, it will be exposed to a charge and discharge cycle in compliance with the manufacturer’s specifications. Short-circuit testing can be performed on subassemblies instead of an entire electrical energy storage assembly (EESA)

Battery crush: runs on fully charged samples and simulates the effect of a vehicle crash on EESA integrity. As with the short-circuit test, a spark ignition detects the presence of flammable concentrations of gases inside the sample, and there can be no signs of explosion or fire. There is no poisonous gas released.

Battery cell crush (vertical): run on fully charged samples. The force applied in the crush test must be limited to 1000 times the weight of the battery. Like the crush test, a spark ignition detects the presence of flammable concentrations of gases inside the sample, and there can be no signs of explosion or fire. There is no poisonous gas released.

LIB test rooms

Safety testing LIBs is an inherently hazardous activity. With deep discharges, short circuits, elevated temperatures, and different types of mechanical abuse, there’s a significant possibility of outgassing, fire, or explosion.

Purpose-designed LIB testing and storage rooms have been developed to mitigate the potential for harm to personnel. One example is a walk-in, 90-minute fire-rated room with internal and external fire protection that can be used as a test chamber or for storing LIBs (Figure 2).

Features designed to protect personnel and the environment include:

- The roof has pressure-relief surfaces to equalize the internal and external pressure in the event of an incident.

- High-performance ventilation for the rapid extraction of harmful or explosive gases.

- The ability to inject inert gases to help contain hazardous reactions or fires.

- Fire sensors to warn of a developing fire and integrated fire extinguishing devices.

- Additional gas sensors are needed to identify outgassing and locations to place more sensors and signal relays.

Figure 2: Walk-in testing and storage room for handling LIBs. (Image: Denios)

Summary

The Li metal content in Lithium-ion batteries means they’re a potential hazard to users of battery-powered systems. LIB safety hazards include discharges that are too deep, short circuits, elevated temperatures, and mechanical abuse. There are dozens of international safety standards and design requirements for LIBs. This FAQ has presented five of the most important ones, along with some basic considerations when specifying a LIB testing room.

References

- A review of international abuse testing standards and regulations for lithium-ion batteries in electric and hybrid electric vehicles, Renewable and Sustainable Energy Reviews

- A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards, “Journal of Energy Chemistry”

- Building Safe Lithium-Ion Batteries for Electric Vehicles: A Review, Electrochemical Energy Reviews

- How to safely pack and ship batteries, UPS

- Li-ion Battery Storage & Testing Building, Denios

- Transport of Lithium Metal and Lithium-Ion Batteries, revised for 2021, IATA

This is an informative and useful post for anyone interested in learning about the top five Li-ion battery safety standards. It’s great to know that there are established guidelines and regulations in place to ensure the safe use, handling, and disposal of these batteries.